The application of non-pressure sintered silicon carbide and reactive sintered silicon carbide

In modern industrial production, silicon carbide is widely used. pressureless sintered silicon carbide and rea ...

In modern industrial production, silicon carbide is widely used. pressureless sintered silicon carbide and rea ...

Reaction sintering silicon carbide ceramics is also called Reaction Bonded Silicon Carbide (RBSiC/SiSiC). R ...

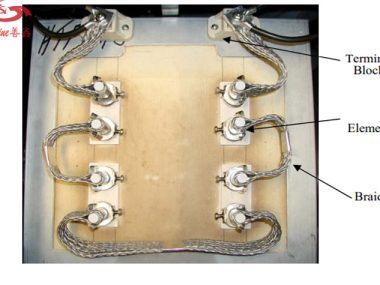

Copper braided wire accessory mosi2 resistance is a heating element with copper connecting wire as electric conductor.

Silicon carbide rods are used for tunnel kilns, roller kilns, glass kilns, vacuum furnaces, muffle furnaces, smelting furnaces and various heating equipment.

The molybdenum disilicide (mosi2) heating element should be installed vertically on the top of the furnace, and the element should be fixed in place by the support clamp to avoid mechanical stress and deformation.

the improvements of 1900 Grade mosi2 heating element compared with 1700 Grade mosi2 heating element

The damage to mosi2 heater caused by too close distance between the heaters and the bottom of the furnace.

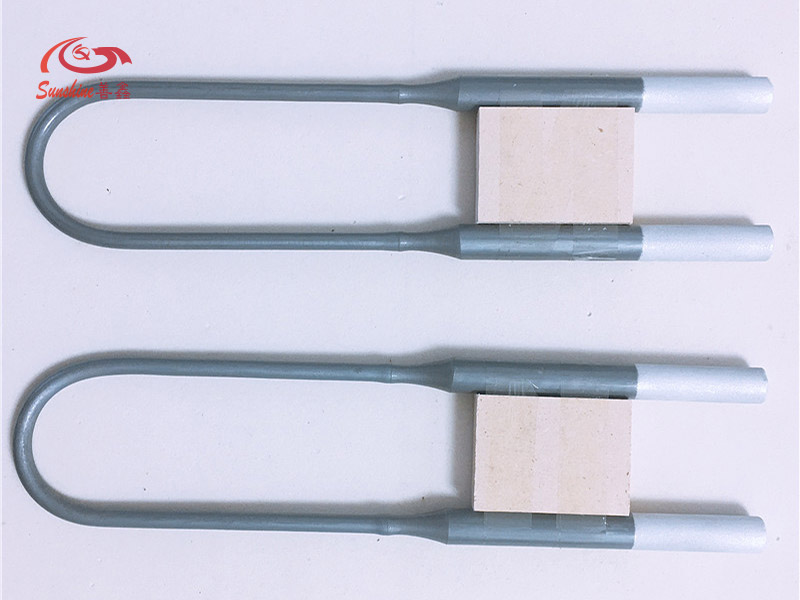

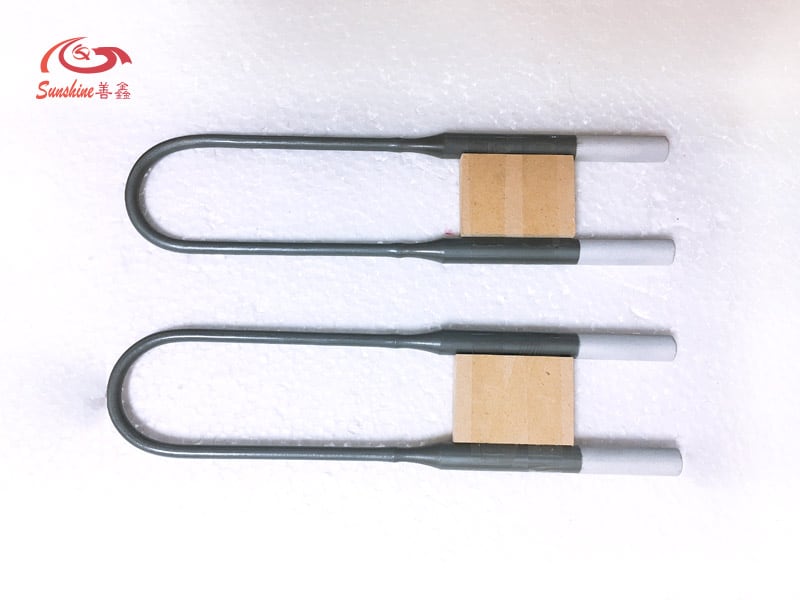

MoSi2 heater rod is a type of molybdenum disilicide resistance element that can withstand high temperatur ...

Mosi2 heater rod has excellent high temperature oxidation resistance, but at lower temperatures, especially 400-700 degrees, it will undergo low temperature oxidation and powdering phenomenon

If the matched accessories is not firm,the heating body will drop and deform severely due to gravity on one or both legs,causing contact and collision with the furnace lining and damage ,and finally it may cause the mosi2 heating resistance element to break or deform.

The layout of molybdenum disilicide heating elements means the interval, shape and installation way of the heating elements inside the furnace, to guarantee the heating performance and lifespan.

Mosi2 heating elements have a certain degree of soft plasticity at high temperatures. The details such as the ...

The connection methods of silicon carbide heater rods Silicon carbide heater rods are a kind of electrode m ...

Erosion of the matched fixture to molybdenum disilicide heating elements at high temperatures is a common problem, affecting their lifespan and performance. Multiple methods to help you solve this problem.

Mosi2 heating elements are classified based on temperature range, including 1700 Grade, 1800 Grade, 1850 Grade, and 1900 Grade. Operating above the rated temperature will result in damage to the heating element.

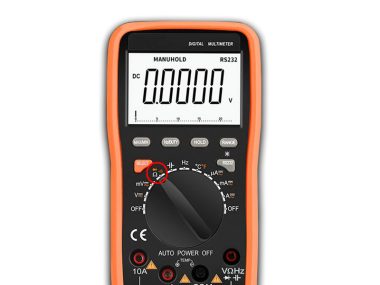

A Step-by-Step Guide to Testing Heating Elements Using a Multimeter

Proper installation and maintenance of Mosi2 heating elements are critical steps in ensuring their longevity a ...

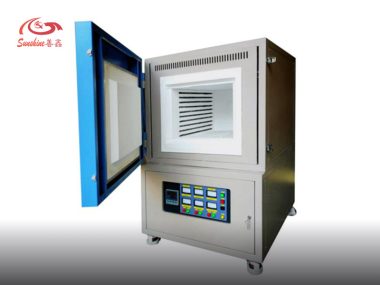

The laboratory furnace is made of high-temperature refractory materials and can be heated continuously for a long time.

Learn about the various shapes of Mosi2 heating elements, including straight, bent, U-shaped, W-shaped, and spiral, and which applications they are best suited for.

To compute the power in watts on the mosi2 heating element the length of the hot zone, the surface area of the ...