Professional heating element supplier in China

High Temperature Materials Wholesaler

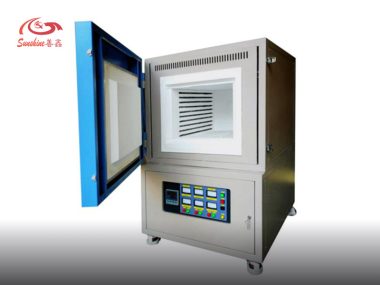

Henan SUNSHINE high temperature materials CO., LTD specialized in manufacturing Molybdenum Disilicide (MoSi2) heating elements,Silicon Carbide Heating Elements and other high temperature materials more than 20 years.

In the last 20 years, Sunshine has branched out into various other fields of manufacturing, namely ceramic fiber, fire brick, industrial furnaces and furnace accessories and other related silicon carbide and silicon nitride products.

Silicon Carbide & Mosi2 Heating Elements

We manufacture and supply electric furnace heating rods in various specifications

Copper braided wire accessory mosi2 heater

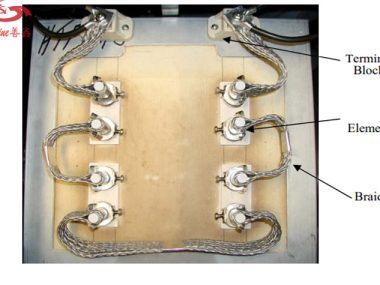

Copper braided wire accessory mosi2 heater is a kind of copper braided strap and molybdenum disilicide heating element closely combined by a special technology to form an integrated structure.

1900 Molybdenum Disilicide (MoSi2) Heating Element

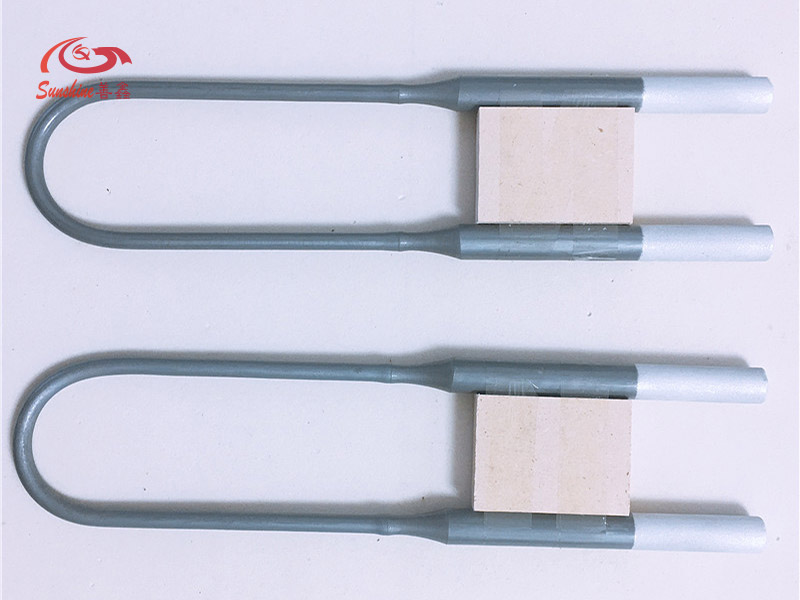

1900 Molybdenum disilicide heating elements are available as straight, U-shaped, W-shaped, L-shaped or bent elements in a wide range of shapes and sizes, all characterized by long life and consistent performance.

Super pure mosi2 heater

Super Pure Mosi2 Heater is the ultimate high-temperature heating solution for industries. Its exceptional performance, high-purity material, and customizability make it the top choice for industries worldwide.

W shape mosi2 heating element

W shape mosi2 heating elements also called Molybdenum disilicide heating element are one mosi2 resistance. It can withstand oxidation at very high temperatures.

U shape mosi2 heating element

U shape Mosi2 heating element can be used in electric furnace for temperatures up to 1900 °C

Straight shape mosi2 heating element

Long service life and anti-corrosion, anti-oxidization are Sunshine ‘s straight shape mosi2 heating element‘s the most obvious advantage.

Thank you for your attention!

Looking forward to working for you!

Furnace and Heater Accessories

We manufacture and supply electric furnaces and related accessories at reasonable prices

SiC silicon carbide tube

Silicon carbide protection tube has high strength properties comparable to diamond, it has excellent thermal conductivity, low thermal expansion, and acid resistance. used to protect temperature sensors from damage in harsh environments, particularly at high temperatures and in corrosive atmospheres.

Are you looking for high-quality heating element suppliers?

Our Blog

Knowledge of electronic heating elements

The application of non-pressure sintered silicon carbide and reactive sintered silicon carbide

In modern industrial production, silicon carbide is extensively used. pressureless sintered silicon carbide and reaction sintered silicon carbide are two primary methods of preparation. Both of these two methods have their own characteristics and and work well in certain situations. Let us summarize briefly the differences of t non-pressure sintered silicon carbide and reactive sintered […]

What is Reaction sintered silicon carbide ceramics?

Reaction sintering silicon carbide ceramics is also called Reaction Bonded Silicon Carbide (RBSiC/SiSiC). Reaction sintered silicon carbide uses a certain particle size distribution of silicon carbide (generally 1~10μm) and carbon mixed and formed green body, and then reacts with silicon at high temperature, part of silicon and carbon react to form SiC and combine with […]

What is Copper braided wire accessory mosi2 resistance

Copper braided wire accessory mosi2 resistance is a heating element with copper connecting wire as electric conductor.

What should we pay attention to when installing and replacing silicon carbide rods?

Silicon carbide rods are used for tunnel kilns, roller kilns, glass kilns, vacuum furnaces, muffle furnaces, smelting furnaces and various heating equipment.

Installation guide for Molybdenum disilicide (mosi2) heating element

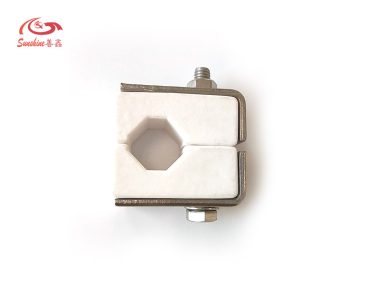

The molybdenum disilicide (mosi2) heating element should be installed vertically on the top of the furnace, and the element should be fixed in place by the support clamp to avoid mechanical stress and deformation.

What are the improvements of 1900 Grade mosi2 heating element compared with 1700?

the improvements of 1900 Grade mosi2 heating element compared with 1700 Grade mosi2 heating element

Heating elements are consumable. I have cooperated with several Chinese manufacturers, SUNSHINE's products are of reasonable price and good quality!

I like SUNSHINE's products, the failure rate is low, we have been using SUNSHINE's heaters and accessories. not just because of the price.

Compared with other brands of heaters, SUNSHINE has stable quality, long service life and high efficiency. The production capacity has also increased by 5% in the last quarter.