MoSi2 heating resistance element is a kind of high temperature and oxidation resistance heating element made from Molybdenum Disilicide. It can be used in air and various gases environments. Working temperature of MoSi2 heating element is 1300℃ to 1800℃.

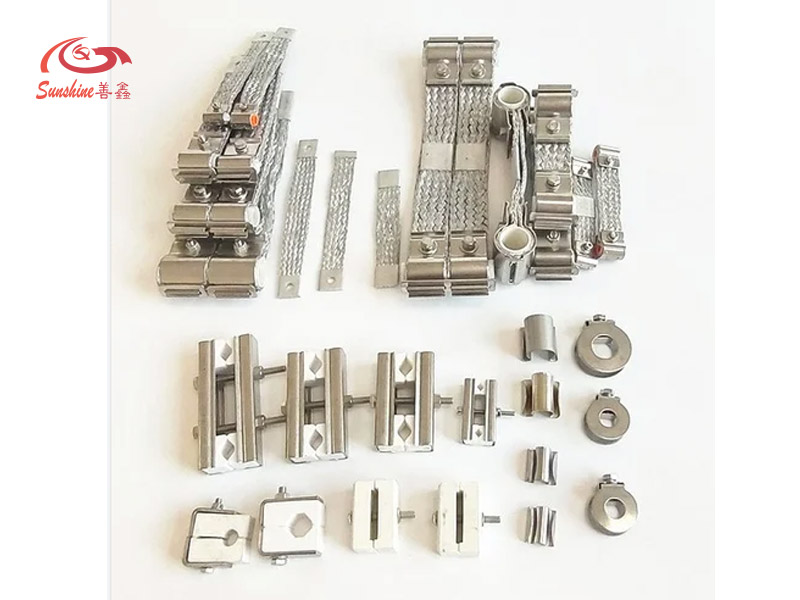

The matched accessory is a device used to fix the mosi2 heating resistance elements. If the fixtures is not firm,the heating body will drop and deform severely due to gravity on one or both legs, causing contact and collision with the furnace lining and damage, and finally it may cause the mosi2 heating resistance element to break or deform.

Mosi2 heating element two shank holders

Mosi2 heating element single shank holders

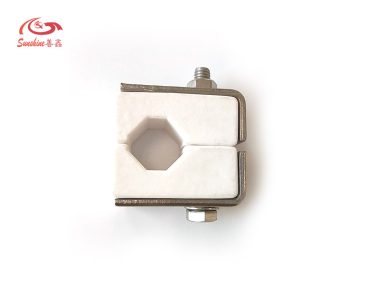

Mosi2 heating element plate holders

Mosi2 heating element combination straps

Mosi2 heating element C contact clamp

Mosi2 heating element holders

How to install mosi2 heating element accessories?

Attention for mosi2 heating element fixture installation

Tighten the fixture screws, and wait until the furnace heats up and the fixed screws expand due to heating, which may cause loosening, causing the heating body to slide down under the action of gravity, the hot end to twist and deform, and even cause the element to break.

Therefore, when installing and using the fixture for the first time, wait until the furnace heats up and then tighten the screws again (if the sintering cycle is short, you can wait until it cools down and tighten again.)

Aluminum braided Connection installation

Adjust the aluminium braided connection through-hole slightly larger than the diameter of the cold end of the heating element, install the aluminium braided connection on the aluminum-sprayed part of the heating element, and tighten the screws.

This part also has the problem of aluminium braided connection or screw thermal expansion and contraction during use, causing poor contact between the aluminium braided connection and the heating element, generating heat or even arc, which will cause low-temperature oxidation or arc melting of the element.

Therefore, you should also wait until the furnace start and then tighten the aluminium braided connection and fixing screw again to avoid problems in this part.