Horizontal and vertical orientation are the more common installation method. Special attention must be paid when mounting to ensure that the elements are not placed in tension. There should be adequate space to allow for the furnace and elements to expand and contract independently.

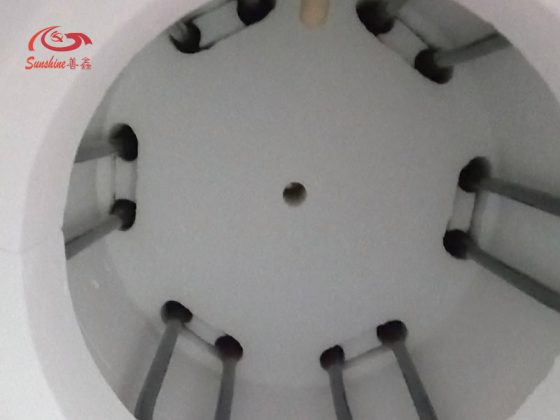

When mounting elements vertically, they must be supported on the lower end by electrically insulated supports, or from above using support pins on an isolating plate of sufficient strength to support the weight of the elements.The elements ends should extend beyond the furnace cold face by a minimum distance of 76.2mm to 101.6mm.

- 1) In order to keep furnace temperature and the load-bearing uniform of each element, before installation, resistance distribution must be carried out. The resistance value deviation of each group should be below 10%.

- 2) As the element is very brittle, be careful while install and maintain to avoid any damage.

- 3) When start to operate the furnace, raise voltage slowly and gradually, never give full load at one time, or the heating element will be damaged by over current impulse.

- 4) To use the elements, you should prepare the adjustable transformer or silicon controlled transformer, voltage meter, current meter and auto control temperature meter etc. During the working, the voltage should be increased to maintain the furnace normal temperature because the resistance value will go up gradually caused y the oxidation of element. When the voltage gets to the up limit of the requirement, the furnace should be stoopoped, change the way of wire connection and then continue work.

- 5) In the course of long operation of the furnace, if any individual heating element is damaged owing to certain reasons and should be changed, you should replace it with proper one whose resistance value corresponds to that of the old one, never use a new heating element random. If the heading element is much damaged or its resistance value increases too much and cannot reach the furnace temperature, it is better to replace the heating elements with mew ones. Test and mark the resistance value of the old elements having been replaced (with voltmeter and ammeter) and distribute them in low temperature area.

- 6) Before the new furnace of the furnace that has not been used for a long time is used, they must be dryinged. When drying them, it is better to use old elements or other heat source.

- 7) When firing appatatus or material, if there is water ejection, the furnace should have holes to eject water vapor or other waste gases in order to protect the elements service life.