DB type silicon carbide heater rod general introduction

DB type silicon carbide heater rods consist of a hot zone with high electrical resistivity and rigidly connected with two thickened cold zones of low resistance owing to their larger diameter and special manufacturing technique.

The particular connecting technique ensures perfect mechanical and electrical operation. Hot zones and cold zones are made of exceptionally homogeneous, self-bonded silicon carbide.

| Material | Silicon carbide, Silicon Carbide (SiC) |

| Power Source | Electric |

| Production process | Made into blank, silicided under high |

| Packing | Cartoon box inside ,Polyfoam filled, Wooden box outside |

| After-sales Service Provided | Overseas service center available |

| flexure strength | 50MPa |

| porosity | 23% |

| Heat conductivity (hot end) | 12-18W/m+℃ at 1000℃ |

| specific heat | 1.0 kj/kg+℃ at 25℃-1300℃ |

| Specific resistance (hot end) | 0.08Ω cm at 1000℃ |

| The coefficient of thermal expansion | 4.5X10-6 |

Video

Installation method about DB type silicon carbide heater rods

DB type silicon carbide heater rods are self-supporting and can be installed vertically or horizontally.

Model number and reference data sheet about DB type silicon carbide heater rods

| Hot zone | Cold Zone | Overall length (mm) | Resistance at 1400℃ (Ω ) | Max.of Loads, Watts(w),Voltage(v)and Current(A)at different temperature | ||||||||

| Dia(mm) | Length(mm) | Surface(mm) | Dia(mm) | Length(mm) | 1100℃ | 1200℃ | 1250℃ | 1300℃ | 1350℃ | 1400℃ | ||

| 8 | 150 | 38 | 14 | 150 | 450 | 3.60 | 900 | 790 | 675 | 520 | 380 | 190 |

| 57/15.8 | 53/14.7 | 49/13.8 | 43/12.0 | 37/10.3 | 26/7.2 | |||||||

| 180 | 45 | 14 | 60 | 300 | 4.40 | 1080 | 950 | 815 | 635 | 460 | 230 | |

| 69/15.7 | 65/14.7 | 60/13.8 | 53/12.0 | 45/10.2 | 32/2.7 | |||||||

| 180 | 45 | 14 | 150 | 480 | 4.40 | 1080 | 950 | 815 | 635 | 460 | 230 | |

| 69/15.7 | 65/14.7 | 60/13.8 | 53/12.0 | 45/10.2 | 32/2.7 | |||||||

| 14 | 200 | 88 | 22 | 250 | 700 | 1.80 | 2110 | 1850 | 1570 | 1230 | 880 | 440 |

| 62/34.0 | 58/32.0 | 53/29.6 | 47/26.6 | 40/22.0 | 28/15.7 | |||||||

| 250 | 11 | 22 | 250 | 750 | 2.20 | 2640 | 2310 | 1980 | 1540 | 1100 | 550 | |

| 76/34.7 | 71/32.6 | 66/30.0 | 58/26.6 | 49/22.4 | 35/15.8 | |||||||

| 250 | 11 | 22 | 350 | 950 | 2.20 | 2640 | 2310 | 1980 | 1540 | 1100 | 550 | |

| 76/34.7 | 71/32.6 | 66/30.0 | 58/26.6 | 49/22.4 | 35/15.8 | |||||||

| 300 | 132 | 22 | 250 | 800 | 2.60 | 3160 | 2770 | 2370 | 1850 | 1320 | 650 | |

| 90/34.8 | 85/32.6 | 78/30.4 | 69/26.7 | 59/22.4 | 41/15.8 | |||||||

| 300 | 132 | 22 | 350 | 1000 | 2.60 | 3160 | 2770 | 2370 | 1850 | 1320 | 650 | |

| 90/34.8 | 85/32.6 | 78/30.4 | 69/26.7 | 59/22.4 | 41/15.8 | |||||||

| 400 | 176 | 22 | 250 | 900 | 3.50 | 4200 | 3680 | 3150 | 2450 | 1750 | 875 | |

| 121/34.7 | 113/32.5 | 105/30.0 | 93/26.4 | 78/22.5 | 55/15.9 | |||||||

| 400 | 176 | 22 | 350 | 1100 | 3.50 | 4200 | 3680 | 3150 | 2450 | 1750 | 875 | |

| 121/34.7 | 113/32.5 | 105/30.0 | 93/26.4 | 78/22.5 | 55/15.9 | |||||||

| 18 | 250 | 141 | 28 | 250 | 750 | 1.30 | 3370 | 2960 | 2540 | 1970 | 1410 | 700 |

| 66/51.2 | 62/47.8 | 57/44.5 | 51/38.8 | 43/32.8 | 30/23.3 | |||||||

| 250 | 141 | 28 | 350 | 950 | 1.30 | 3370 | 2960 | 2540 | 1970 | 1410 | 700 | |

| 66/51.2 | 62/47.8 | 57/44.5 | 51/38.8 | 43/32.8 | 30/23.3 | |||||||

| 300 | 170 | 28 | 250 | 800 | 1.70 | 4080 | 3570 | 3060 | 2380 | 1700 | 850 | |

| 83/49.2 | 78/45.8 | 72/42.5 | 64/37.2 | 54/31.5 | 38/22.4 | |||||||

| 300 | 170 | 28 | 350 | 1000 | 1.70 | 4080 | 3570 | 3060 | 2380 | 1700 | 850 | |

| 83/49.2 | 78/45.8 | 72/42.5 | 64/37.2 | 54/31.5 | 38/22.4 | |||||||

| 400 | 226 | 28 | 250 | 900 | 2.30 | 5400 | 4740 | 4060 | 3160 | 2260 | 1130 | |

| 111/48.6 | 104/45.6 | 97/41.9 | 85/37.2 | 72/31.4 | 51/22.2 | |||||||

| 400 | 226 | 28 | 350 | 1100 | 2.30 | 5400 | 4740 | 4060 | 3160 | 2260 | 1130 | |

| 111/48.6 | 104/45.6 | 97/41.9 | 85/37.2 | 72/31.4 | 51/22.2 | |||||||

| 500 | 283 | 28 | 350 | 1200 | 2.70 | 6800 | 5960 | 5100 | 3840 | 2860 | 1420 | |

| 135/50.4 | 127/47.0 | 117/43.6 | 102/37.6 | 88/32.5 | 62/23.0 | |||||||

| 600 | 339 | 28 | 250 | 1100 | 3.40 | 8150 | 7140 | 6130 | 4760 | 3400 | 1700 | |

| 166/49.0 | 156/45.7 | 144/42.7 | 127/37.6 | 107/31.8 | 76/22.4 | |||||||

| 600 | 339 | 28 | 350 | 1300 | 3.40 | 8150 | 7140 | 6130 | 4760 | 3400 | 1700 | |

| 166/49.0 | 156/45.7 | 144/42.7 | 127/37.6 | 107/31.8 | 76/22.4 | |||||||

| 800 | 452 | 28 | 250 | 1300 | 4.60 | 10800 | 9500 | 8140 | 6340 | 4530 | 2260 | |

| 222/48.8 | 208/45.7 | 193/42.1 | 171/37.1 | 144/31.5 | 102/22.1 | |||||||

| 800 | 452 | 28 | 350 | 1500 | 4.60 | 10800 | 9500 | 8140 | 6340 | 4530 | 2260 | |

| 222/48.8 | 208/45.7 | 193/42.1 | 171/37.1 | 144/31.5 | 102/22.1 | |||||||

| 25 | 300 | 236 | 35 | 400 | 1100 | 1.00 | 6040 | 4880 | 4080 | 3150 | 2180 | 1175 |

| 77.8/77.8 | 66.9/66.9 | 64/64 | 56.2/56.2 | 46.7/46.7 | 34.3/34.3 | |||||||

| 400 | 314 | 35 | 400 | 1200 | 1.34 | 7350 | 6920 | 5660 | 4400 | 3140 | 1760 | |

| 99/76 | 95/73 | 86/66 | 76/58 | 64/49 | 48/36.5 | |||||||

| 30 | 500 | 472 | 45 | 400 | 1300 | 1.10 | 10800 | 9870 | 8450 | 6570 | 4700 | 2350 |

| 109/99 | 104/95 | 96/88 | 85/77.3 | 72/65.4 | 51/46.2 | |||||||

| 600 | 566 | 45 | 600 | 1800 | 1.28 | 13500 | 11800 | 10300 | 7900 | 5660 | 2820 | |

| 132/102 | 123/96 | 116/89 | 102/77.5 | 86/66 | 61/46.5 | |||||||

| 1000 | 942 | 45 | 500 | 2000 | 2.10 | 22000 | 19800 | 17000 | 13200 | 9400 | 4700 | |

| 214/103 | 204/97 | 189/90 | 160/79 | 140/67 | 100/47 | |||||||

The replacement of DB type silicon carbide heater rods

DB type silicon carbide heater rods can be replaced while the furnace is at operating temperature.

The power to the elements being changed should be shut off, the spring clips and aluminum braid released, and the old Starbar removed.

The new silicon carbide heater rod should be inserted smoothly through the hot furnace with sufficient speed to insure that the aluminum is not melted off the terminal end but not so fast as to cause thermal shock. can be replaced while the furnace is at operating temperature.

The application of DB type silicon carbide heater rods

DB type silicon carbide heater rod is often used in small box furnace, experimental furnace, tunnel furnace, Muffle furnace and so on.

DB type silicon carbide heater rods are often used in ceramics, electronics, magnetic materials, powder metallurgy, rare earth phosphor, lithium battery materials, precision casting and other industries

The advantages of DB type silicon carbide heater rods

The DB type silicon carbide heater rods have the characteristics of high temperature , low aging, fast heating, corrosion resistance, long life and small deformation at high temperature

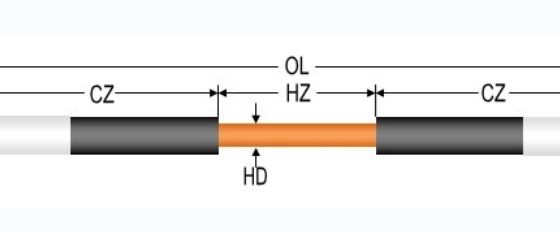

When you inquiry, Please inform us

- Outer diameter (CD) and (HD)

- Length of Hot zone (HZ)

- Cold end length(CZ)

- Length of Overall (OL)

- Vottage and Wattage

- Quantity