Why W shape mosi2 heating element?

This type of mosi2 heating element looks like the letter “W”, so it is called “W shape mosi2 heating element”.

| Application | high temperature electric furnace heating |

| Classification | Furnace heater |

| Main Material | Molybdenum disilicide MoSi2 |

| Supply Ability | 5000 Piece/Pieces per Week for W shape MoSi2 heating element |

| Experience in Making | 20 years Heater Element |

| Volume Density | 5.8 ~ 6.2g/cm³ |

| Bending Strength | 15 – 25kg/cm³ |

| Vickers Hardness | (HV)570 kg/mm² |

| Porosity | 7.40% |

| Water absorption | 1% |

| Heating Elongation Rate | 4% |

| Size | customized |

| Packing | cartoon box inside, Polyfoam filled, Wooden box outside |

| After-sales Service Provided | Overseas service center available |

Standard specification

Two-Shank Elements

Manufactured to industry established diameters and resistance values in the following diameters: 3/6, 4/9, 6/12, 9/18 and 12/24.

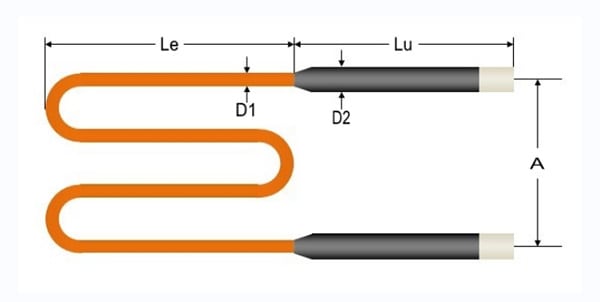

Mosi2 heating element length:Lu length from 150 to 1000mm,Le length from 150 to 1500mm,customized is available.

MoSi2 heating element operation temperature: from 500C to 1750℃. Max temperature can up to 1900 ℃

MoSi2 heating element rod shape: U type; W type; straight type; L type.

Reference data for W shape mosi2 heating element

| Diameter(mm) φd(hot zone)/ φc (cold zone) | shape | length(mm) Le(hotzone)/Lu(cold zone) | a(mm) | g(mm) | f(mm) | h(mm) | n(mm) | ||

| Standard | Minimum | Standard | Minimum | Standard | Minimum | ||||

| 3/6 | U shape,L shape,W shape or customized | customized | 25 | 12 | 15 | 30 | 10 | 40 | 35 |

| 4/9 | U shape,L shape,W shape or customized | customized | 25 | 15 | 20 | 30 | 10 | 50 | 45 |

| 6/12 | U shape,L shape,W shape or customized | customize | 50 | 25 | 25 | 45 | 15 | 90 | 70 |

| 9/18 | U shape,L shape,W shape or customized | customized | 60 | 35 | 32 | 75 | 20 | 135 | 110 |

| 12/24 | U shape,L shape,W shape or customized | customized | 80 | 50 | 40 | 100 | 35 | ||

The Resistivity of W shape mosi2 heating element

The resistivity of MoSi2 increases with temperature. When connected to a constant voltage, the elements attain high power at lower temperatures and the power gradually reduces with the increasing temperature, This shortens the time of the furnace to achieve the operating temperature. However, as the power of the elements reduces, the probability of element overheating also reduces.

The resistance of MOSI2 Heating element) does not age even when exposed to high temperatures during operation. The resistance drops only by a slight amount (≈ 5%) during the first period.

Due to the availability of such properties, a failed component can easily be replaced without affecting the performance of other components connected in series.

Video

The unique characteristics of W shape mosi2 heating element

W shape mosi2 heating element is manufactured with high-grade materials and unique formula in combination with international hot-bending technology. The “three U-shaped” radians of the rod are uniform and symmetrical, and the appearance is neat. W shape mosi2 heating element has better thermal shock resistance, better creep resistance and longer service life.

1.The surface is treated with special coating treatment, clean appearance, long service life;

2.W shape mosi2 heating element center distance is large, the hot end layout density is large.compared with the U shape molybdenum disilicide heating element with the same layout density it has less U- cold and hot end interface, less wiring between components, small loss;

3.W shape mosi2 heating element is treated with two cold ends spray aluminum treatment and has strong conductive property;

4.W shape mosi2 heating element is suitable for large electric kiln with components layout density, less wiring, general horizontal installation, three U-shaped bending part by corundum cushion brick support.

Two-shank elements with straight terminals are defined by

- Element grade 1700 Grade, 1800 Grade,1850 Grade, 1900 Grade or Super pure Type

- Heating zone diameter “d”, mm

- Terminal diameter “c”, mm

- Terminal length “Lu”, mm

- Heating zone length “Le”, mm

- Center distance between shanks “a”, mm

Example: 1800 Grade,9/18, Lu = 320 mm

Sizes Available

Le = 510 mm

A=50mm

As shown below: