What is L shape mosi2 heating element?

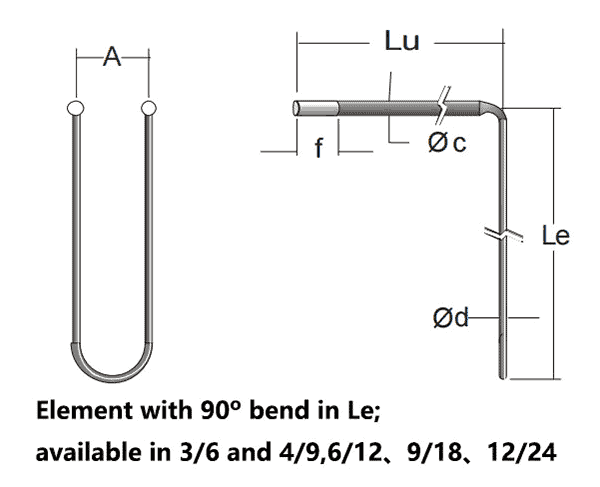

L shape mosi2 heating element looks like the letter “L” from the side. Commonly used sizes are 90 degrees and 45 degrees, but other angles can be custom manufactured.

L shape mosi2 heating element specification

Two-Shank Elements

1.Manufactured to industry established diameters and resistance values in the following diameters: 3/6, 4/9, 6/12, 9/18 and 12/24.

2.MoSi2 heating element length: Lu length from 150 to 1000mm, Le length from 150 to 1500mm, customized is available

3.MoSi2 heating element operation temperature: from 500℃ to 1750℃. Max temperature can up to 1900℃.

4.MoSi2 rod heating element rod shape: U type; W type; straight type; L type

| Color | gray |

| Application | high temperature electric furnace heating |

| Classification | Furnace heater |

| Packing | cartoon box inside, Polyfoam filled, Wooden box outside |

| After-sales Service Provided | Overseas service center available |

| Key Selling Points | Long Service Life |

| Supply Ability | 5000 Piece/Pieces per Week for MoSi2 heating element |

| Volume Density | 5.8~6.2g/CM3 |

| Bending Strength | 15-25kg/cm3 |

| Vickers Hardness | (HV)570kg/mm2 |

| Porosity | 7.40% |

| Water absorption | 1.20% |

| Heating Elongation Rate | 4% |

L shape mosi2 heating element reference data

| Diameter(mm) φd(hot zone)/ φc (cold zone) | shape | length(mm) Le(hotzone)/Lu(cold zone) | a(mm) | g(mm) | f(mm) | h(mm) | n(mm) | ||

| Standard | Minimum | Standard | Minimum | ||||||

| 3/6 | U shape,L shape,W shape or customized | customized | 25 | 12 | 15 | 30 | 10 | 40 | 35 |

| 4/9 | U shape,L shape,W shape or customized | customized | 25 | 15 | 20 | 30 | 10 | 50 | 45 |

| 6/12 | U shape,L shape,W shape or customized | customized | 50 | 25 | 25 | 45 | 15 | 90 | 70 |

| 9/18 | U shape,L shape,W shape or customized | customized | 60 | 35 | 32 | 75 | 20 | 135 | 110 |

| 12/24 | U shape,L shape,W shape or customized | customized | 80 | 50 | 40 | 100 | 35 | / | / |

Two-shank elements with straight terminals are defined by:

- Element grade 1700 Grade, 1800 Grade,1850 Grade, 1900 Grade or Super pure Type

- Heating zone diameter “d”, mm

- Terminal diameter “c”, mm

- Terminal length “Lu”, mm

- Heating zone length “Le”, mm

- Center distance between shanks “a”, mm

Example: 1800 Grade,9/18, Lu = 320 mm

Sizes Available

Le = 510 mm

A=50mm

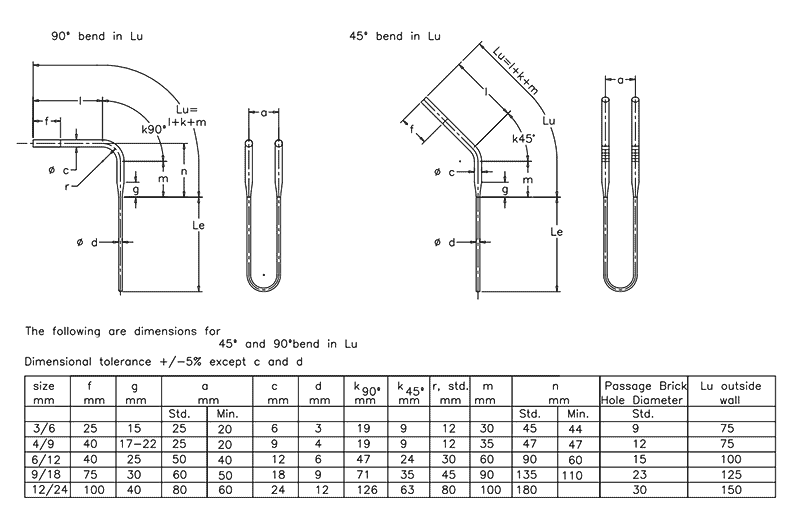

| Size mm | f mm | g mm | a mm | c mm | d mm | k90° mm | k45° mm | r,std. mm | m mm | n mm | Passage Brick Hole Diameter | Lu outside wall | ||

| Std. | Min. | Std. | Min. | Std. | ||||||||||

| 3/6 | 25 | 15 | 25 | 20 | 6 | 3 | 19 | 9 | 12 | 30 | 45 | 44 | 9 | 75 |

| 4/9 | 40 | 17-22 | 25 | 20 | 9 | 4 | 19 | 9 | 12 | 35 | 47 | 47 | 12 | 75 |

| 6/12 | 40 | 25 | 50 | 40 | 12 | 6 | 47 | 24 | 30 | 60 | 90 | 60 | 15 | 100 |

| 9/18 | 75 | 30 | 60 | 50 | 18 | 9 | 71 | 35 | 45 | 90 | 135 | 110 | 23 | 125 |

| 12/24 | 100 | 40 | 80 | 60 | 24 | 12 | 126 | 63 | 80 | 100 | 180 | 30 | 150 | |

The Using Temperature Under the Different Atmospheres

| Atmosphere | The Maximum Using Temperature of Element | ||

| 1700Grade | 1800Grade | 1900Grade | |

| NO2,CO2,O2,Air | 1700 ℃ | 1800 ℃ | 1850 ℃ |

| He,Ar,Ne | 1650 ℃ | 1750 ℃ | 1800 ℃ |

| SO2 | 1600 ℃ | 1700 ℃ | 1800 ℃ |

| CO,H2 | 1500 ℃ | 1600 ℃ | 1700 ℃ |

| WetH2 | 1400 ℃ | 1500 ℃ | 1650 ℃ |

| Dry H2 | 1350 ℃ | 1450 ℃ | 1600 ℃ |

Element Replacement

If there is a damaged part found in the process of operation, the first thing you should do is determine its location and get all the combination elements ready. After that, you should separate the wire the damaged element clipped to from the screw which is connected to the generatrix. Then remove the remained refractory wool and pull out the refractory stoppers. Insert the new combination elements into the furnace from its roof. Connect all the wires and get the refractory wool filled, and finally raise the temperature.

Video

With 20 years experience, Henan Sunshine is your trusted source for quality L shape mosi2 heating element as one of the leading suppliers of various heaters in China. Providing you with the most competitive price, please be free to contact us.