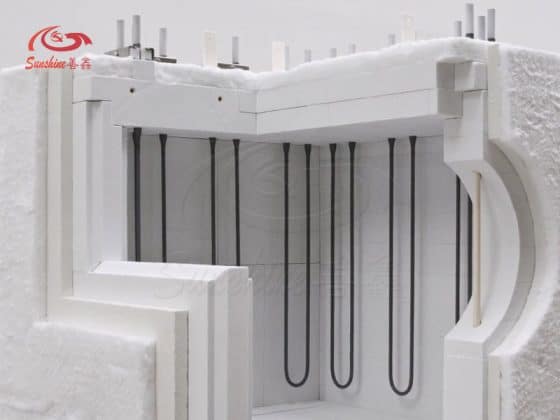

MoSi2 and SiC heating elements are both widely used in high-temperature industrial applications, such as furnaces, kilns, and heat treatment processes.

So is it possible to replace it with another one when replacing it? Below we will discuss whether MoSi2 heating elements can replace SiC heating elements.

What is MoSi2 Heating Element?

MoSi2 heating elements are made of molybdenum disilicide, which has excellent high-temperature stability and oxidation resistance. These properties make MoSi2 heating elements suitable for high-temperature applications up to 1800°C. Additionally, MoSi2 heating elements have a long service life and can provide stable and uniform heating.

What are SiC Heating Elements?

SiC heating elements are made of silicon carbide, which has excellent thermal conductivity, high-temperature stability, and chemical resistance.

They are used in high-temperature applications up to 1600°C and are known for their fast heating and cooling capabilities. SiC heating elements can provide efficient and uniform heating, making them ideal for many high-temperature applications.

Can MoSi2 Replace SiC Heating Elements?

MoSi2 and SiC heating elements have their unique properties that make them suitable for different applications. Therefore, in general, MoSi2 heating elements cannot replace SiC heating elements, and vice versa.

The following factors need to be considered when selecting between MoSi2 and SiC heating elements:

- Temperature Range. The temperature range required for the application is a critical factor when selecting between MoSi2 and SiC heating elements. MoSi2 heating elements can withstand higher temperatures than SiC heating elements, making them suitable for applications that require temperatures above 1600°C.

- Atmosphere: The atmosphere in which the heating element will be used is another critical factor. MoSi2 heating elements are suitable for oxidizing and neutral atmospheres, while SiC heating elements are more suitable for reducing and inert atmospheres.

- Power Requirements: The power requirements of the application also need to be considered. MoSi2 heating elements have a higher resistance than SiC heating elements, which means they require higher voltage and lower current to achieve the same power output.

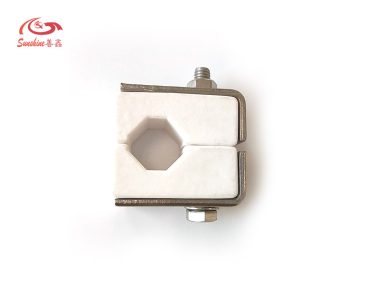

- Installation, usually the installation position of the electric heating furnace has been reserved during production, and heating elements of specific specifications are required to be installed correctly.

- Cost. The cost of the heating element is also an important factor. MoSi2 heating elements are generally more expensive than SiC heating elements because of the price of raw materials, which is also a consideration when choosing between the two.

In conclusion, MoSi2 heating elements and SiC heating elements have their unique properties that make them suitable for different applications. While MoSi2 heating elements may have advantages in some applications, they cannot replace SiC heating elements in all cases.

The selection between the two should be based on the temperature range, atmosphere, power requirements, and cost of the application.