Electric heating elements are used in a wide range of high temperature heating applications, both in industrial production and in household appliances.

Material composition of different types of heating elements

The material composition of the various heating elements varies due to the different scenarios in which they are used and the different properties required of the heating rods in various environments.

Silicon Carbide Heating Elements(sic heating elements)

Silicon carbide heating elements are made of selected super green silicon carbide.Silicon carbide heating elements are also called “sic heating elements”.

It is characterized by good high temperature stability, high thermal conductivity and fast heating rate. Silicon carbide heating elements are usually used in heating scenarios where fast heating and high temperature stability are required, such as industrial production heating and laboratory heating.

Silicon carbide heating elements in different types

U type silicon carbide heating element

SGR type Double Spiral Silicon Carbide Heating Element Max temperature 1625 ℃

SG type SiC heating elements(single spiral)

M type Globar silicon carbide heating element

Alkali resistant Coating SiC heater

DB type silicon carbide heater rod

MoSi2 Heating Elements

MoSi2 heating elements, also known as molybdenum disilicide heating elements, are made of high pure molybdenum disilicide.

It is characterized by its high melting point and excellent high-temperature stability, which makes it ideal for high-temperature heating applications. MoSi2 heating elements will last longer than other heating elements due to the structural changes that occur when they are heated, increasing their resistance to high temperatures.

MoSi2 heating elements in different shapes

W shape mosi2 heating element

U shape mosi2 heating element

Straight shape mosi2 heating element

L shape mosi2 heating element

Other common electric heating elements

In addition to silicon carbide heater rods and MoSi2 heating elements, there are several other common electric heating elements being used for high temperature heating, including.

NiCr heating elements. NiCr is a nickel-chromium alloy that has high oxidation resistance and good electrical conductivity.

Tungsten heating elements. Tungsten is a high density, high melting point metal, due to its good high temperature stability and oxidation resistance, is also used in heating elements, more common in daily life, such as electric heating fans used for indoor heating in winter, the heating element used in electric heating air is used in tungsten heating.

Choosing the right electric heating element

When choosing an electric heating element, the most suitable heating element must be selected for the specific heating requirements, including temperature range, working environment and service life. Each type of heating element has different performance and different use scenarios.

Electrical heating elements are a central component of the high-temperature heating process. They can be made from a variety of materials, including silicon carbide, MoSi2, nickel-chromium and tungsten. Different types of heating elements have their own unique properties and different use scenarios, so it is important that I choose the right heating element to ensure optimal performance and service life in my use.

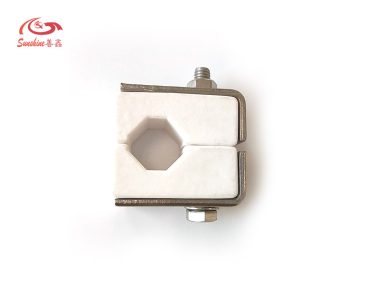

Sunshine Heating Elements manufactures and supplies reliable, durable Silicon carbide heating elements and MoSi2 Heating Elements with associated holders, clamps, and aluminum braided straps / copper braided straps, and other accessories.

Contact us now for discounted pricing.