What are Silicon Carbide Heating Elements?

Material and process

Silicon carbide heating elements, also known as globar sic heating elements or silicon carbide rods, are rod-shaped non-metal high-temperature heating elements made of high-quality green silicon carbide as the main raw material, processed, returned, high-temperature silicified and recrystallized.

Specification

| Material | Silicon Carbide(SIC) |

| Temperature | 200 ℃~1625 ℃ (392℉ – 2957℉) |

| Diameters | 10 mm – 55 mm |

| Hot zones | Max 4.2 m |

| Lengths | 100 mm – 6 m |

| Shape | slot type, U type, SGR type, SG type, M type, ED type, DB type |

| Coating | Alkali resistant Coating, A Coating, B Coating |

Temperature

Silicon carbide (SiC) heating elements can withstand temperatures up to 1625℃(2957℉), making them ideal for high-temperature applications. We offer a variety of standard sizes and geometries, as well as custom designs to meet specific requirements for various processes and equipment.

Advantage

Silicon carbide heating element is a time trusted heating element. It has the advantages of small hot-end resistance, long service life, and energy saving.Silicon Carbide heating elements are available in eight different basic configurations that extend heater life especially in corrosive environments.

The mosi2 heating element is also a heating element used in electric furnaces, and the price is slightly more expensive than the sic heating element.

What is sic element?

Silicon carbide (SiC), also known as carborundum, is a hard compound containing silicon and carbon. As a semiconductor, silicon carbide particles can be combined through sintering to form a very hard ceramic, hardness approaching that of diamond.

The commonly used types of silicon carbide heating elements are:

- sg type silicon carbide heating element

- ed type silicon carbide heating elements

- w type silicon carbide heating elements

- sgr type silicon carbide heating elements

- u type silicon carbide heating elements

- ld type silicon carbide heating elements

B coating silicon carbide heating elements

A coating silicon carbide heating element

U type silicon carbide heating element

SGR type Double Spiral Silicon Carbide Heating Element Max temperature 1625 ℃

SG type SiC heating elements(single spiral)

Physical Properties

| Specific gravity | 2.6~2.8g/cm³ | Bend strength | >300kg |

| Hardness | >9MOH’S | Tensile strength | >150Kg.cm³ |

| Porosity rate | <30% | Radiancy | 0.85 |

| Thermal Conductivity | 14-19W/m·℃ (1000℃) | Specific Heat | 1.0kj/kg·℃ (25~1300℃) |

| Rupture Strength | 50Mpa(25℃) | Coefficient Of Thermal Expansion | 4.5x 10-5 |

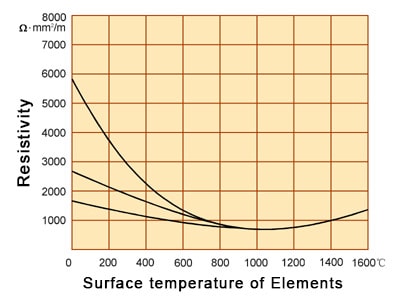

Electrical characteristics

Globar sic heating elements has rather large specific resistance. When it is heated in air and the surface temperature of the hot zone reaches 1050℃(2732℉), its resistance rate is 600-1400 mm²/m. Its resistance value changes as the temperature rises.

From room-temperature to 800℃(1472℉) is negative value, over 800℃ is positive value nature curve.

All silicon carbide elements gradually increase in resistance during their life in operation and the rate at which this occurs is affected by the following factors:

- Element type

- Element Specific Loading (W/cm²)

- Operating Temperature

- Process Atmosphere

- Mode of operation – continuous or intermittent

- Operating practices

Video

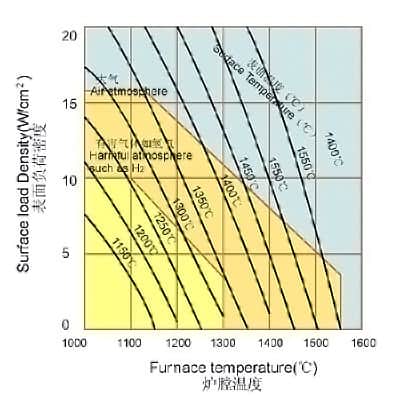

Element Surface Loading

The key factor to the optimum service life of the element is to select the surface load of the element correctly according to the furnace construction, atmosphere and temperature below.

The curves show maximum specific element loading for different element types operated in air. These values may be used as a guide, but for maximum element life a lower loading should be used wherever possible.

A lower loading may also be required where elements are to be operated in reducing or other process atmospheres, to maintain element temperatures within the limits, see table below.

| Temperature(℃) | Linear expansion coefficient (10-6m/℃) | Heat conductivity (Kcal/M hr ℃) | specific heat (cal.g℃) |

| 0 | / | / | 0.148 |

| 300 | 3.8 | / | / |

| 400 | / | / | 0.255 |

| 600 | 4.3 | 14-18 | / |

| 800 | / | / | 0.294 |

| 900 | 4.5 | / | / |

| 1100 | / | 12-16 | / |

| 1200 | 4.8 | / | 0.325 |

| 1300 | / | 10-14 | / |

| 1500 | 5.2 | / | / |

Application of Sic Heating Elements

Therefore, silicon carbide rods are widely used in various high-temperature electric furnaces and other electric heating equipment in the industries of magnetic materials, powder metallurgy, ceramics, glass, metallurgy and machinery.

Accessories

Stainless steel M type terminal clamps

Stainless steel G clamps

Stainless steel C clamps

Aluminum braided straps

Si3N4 silicon nitride protection tube

SiC silicon carbide tube

Sic heating elements VS metal electric heating elements

Compared with metal electric heating elements, Globar sic heating elements have the characteristics of high operating temperature, oxidation resistance, corrosion resistance, long life, low deformation, and convenient installation and maintenance.

FAQ:

How to choose power supply equipment?

Power supply equipment should be selected with a large regulating range voltage and it is a stable and continuous voltage regulating equipment, such as magnetic voltage regulator, silicon controlled DC voltage regulator, etc. If you choose a stage voltage regulator transformer, you should also choose a transformer with a small voltage difference.

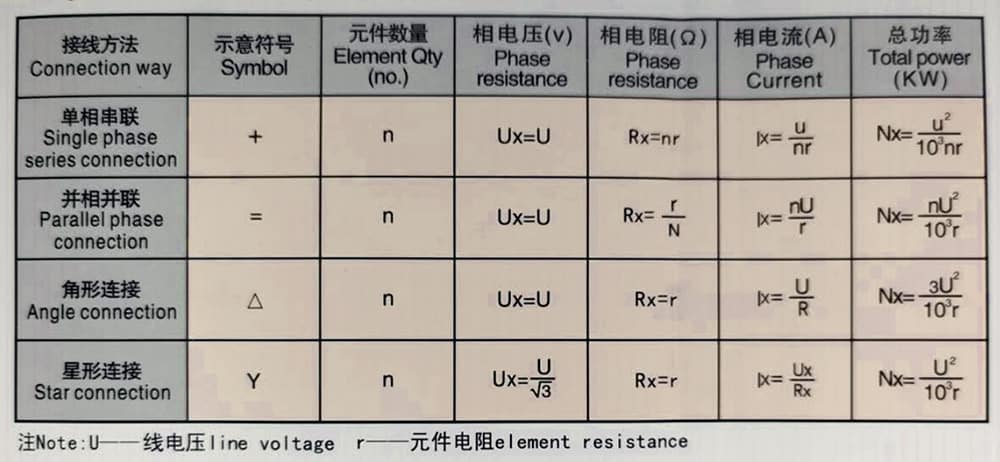

What are the connection of silicon carbide rods?

The connection mode of silicon carbon rod element can be series or parallel, and parallel is the best. When used in series, the number of branches in series should not be more than 3.

The Common connection methods and their calculation formulas are listed in the following datatable.

Please follow the steps in the following article when replacing and installing globar sic rods.

Silicon Carbide Rod Installation Operation Guide

How to prolong the element’s service life?

The resistance value of the heating element will increase and age with the extension of service time. When the resistance of the element increases to 3 times the initial resistance value, it is regarded as the end of service life. There are several factors affecting the aging and life reduction of heating elements:

- Operating temperature

- Electrical loading (usually expressed in watts per square inch or watts per square centimeter of elements radiating surface)

- Atmosphere

- Type of operation (continuous or intermittent)

- Operating and maintenance techniques

When used in 1450 ℃(2642℉) clean oxidation atmosphere, the heating element can obtain a relatively long service life. In order to achieve the best service life, the surface load as low as possible should be considered when designing the furnace, and 3-8w/cm² is recommended

Silicon Carbide Heating Element Supplier

Sunshine as a factory and supplier of Silicon Carbide Heating Elements, we offer high-quality products that are designed to meet the demands of various heating applications. Our heating elements are made from high-purity silicon carbide materials, ensuring excellent thermal stability, mechanical strength, and resistance to oxidation and corrosion.

We provide a wide range of heating element designs and sizes to accommodate the needs of different industries, such as semiconductor manufacturing, metallurgy, ceramics, and glass processing.

With years of experience in the industry, our team of experts is dedicated to providing superior customer service and technical support to ensure the success of your heating system. Choose us as your trusted partner for all your Silicon Carbide Heating Element requirements, and experience。

As a leading manufacturer of SiC heating elements, we are committed to providing high-quality products that are optimized for performance and durability. Contact us today to learn more about our SiC heating elements and how they can improve your industrial heating applications.