What is u shape mosi2 heating element?

The u shape mosi2 heating element looks like the letter “U” in English, it is durable and reliable at high temperatures.

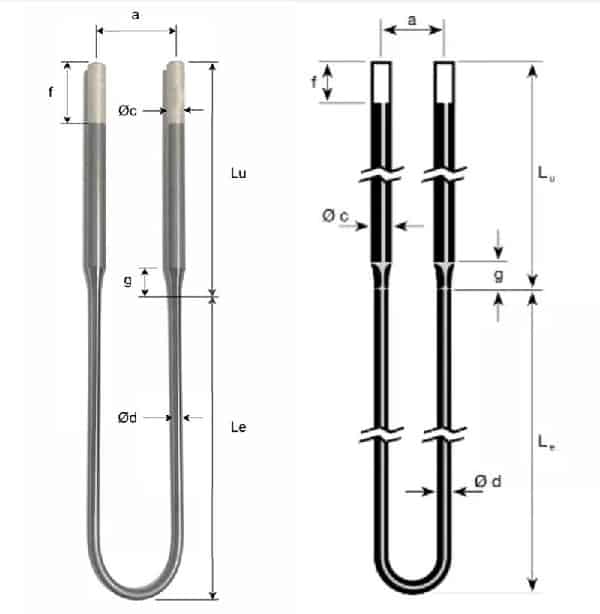

The U shaped mosi2 heating elements are most frequently used suspended with the bottom of the “U” down. The element consists of two cold ends (Lu) and a U-shaped hot section (Le).

The cold ends are twice the diameter of the hot section and are attached by a weld. The extremities of the cold ends are metallized with aluminum to provide a low-resistance contact surface to which the electrical connections are made with flat braided aluminum straps.

| Main Material | Molybdenum disilicide MoSi2 |

| Classification | Furnace heater |

| Key Selling Points | Long Service Life |

| Supply Ability | 5000 Piece / Pieces per Week for molybdenum disilicide heating element |

| Volume Density | 5.8~6.2g/cm³ |

| Bending Strength | 15-25kg/cm³ |

| Vickers Hardness | (HV)570kg/mm² |

| Porosity | 7.40% |

| Water absorption | 1.20% |

| Heating Elongation Rate | 4% |

| Packing | Cartoon box inside,Polyfoam filled, Wooden box outside |

| After-sales Service Provided | Overseas service center available |

These mosi2 heating elements are available in two grades: 1700 for element temperatures up to 1700 ℃ and 1800 for element temperatures up to 1850 ℃.

Standard specification

Two-Shank Elements

Manufactured to industry established diameters and resistance values in the following diameters: 3/6, 4/9, 6/12, 9/18 and 12/24.

Mosi2 heating element length:Lu length from 150 to 1000mm, Le length from 150 to 1500mm, customized is available.

Mosi2 heating element operation temperature: From 500C to 1750 ℃. Max temperature can up to 1900 ℃

Mosi2 heating element rod shape: U type; W type; straight type; L type.

Reference data for U shape mosi2 heating element

| Diameter(mm) φd(hot zone)/ φc (cold zone) | shape | length(mm) Le(hotzone)/Lu(cold zone) | a(mm) | g(mm) | f(mm) | h(mm) | n(mm) | ||

| Standard | Minimum | Standard | Minimum | ||||||

| 3/6 | U shape,L shape,W shape or customized | customized | 25 | 12 | 15 | 30 | 10 | 40 | 35 |

| 4/9 | U shape,L shape,W shape or customized | customized | 25 | 15 | 20 | 30 | 10 | 50 | 45 |

| 6/12 | U shape,L shape,W shape or customized | customize | 50 | 25 | 25 | 45 | 15 | 90 | 70 |

| 9/18 | U shape,L shape,W shape or customized | customized | 60 | 35 | 32 | 75 | 20 | 135 | 110 |

| 12/24 | U shape,L shape,W shape or customized | customized | 80 | 50 | 40 | 100 | 35 | ||

The installation of U shape mosi2 heating element

Two-shank elements with straight terminals are defined by

- Element grade 1700 Grade, 1800 Grade,1850 Grade, 1900 Grade or Super pure Type

- Heating zone diameter “d”, mm

- Terminal diameter “c”, mm

- Terminal length “Lu”, mm

- Heating zone length “Le”, mm

- Center distance between shanks “a”, mm

Example: 1800 Grade,9/18, Lu = 320 mm

Sizes Available

Le = 510 mm

A=50mm

As shown below:

Resistance coefficient of mosi2 heating element

| Element temperature (℃) | Type 1700 resistivity (Ω·mm2/m) | Type 1800 resistivity (Ω·mm2/m) |

| 20 | 0.306 | 0.286 |

| 100 | 0.448 | 0.398 |

| 200 | 0.622 | 0.550 |

| 300 | 0.816 | 0.724 |

| 400 | 1.020 | 0.907 |

| 500 | 1.224 | 1.102 |

| 600 | 1.418 | 1.306 |

| 700 | 1.632 | 1.509 |

| 800 | 1.846 | 1.714 |

| 900 | 2.071 | 1.918 |

| 1000 | 2.285 | 2.142 |

| 1100 | 2.499 | 2.366 |

| 1200 | 2.734 | 2.601 |

| 1300 | 2.968 | 2.836 |

| 1400 | 3.223 | 3.050 |

| 1500 | 3.488 | 3.315 |

| 1600 | 3.743 | 3.570 |

| 1700 | 4.029 | 3.805 |

| 1800 | 4.316 | 4.060 |

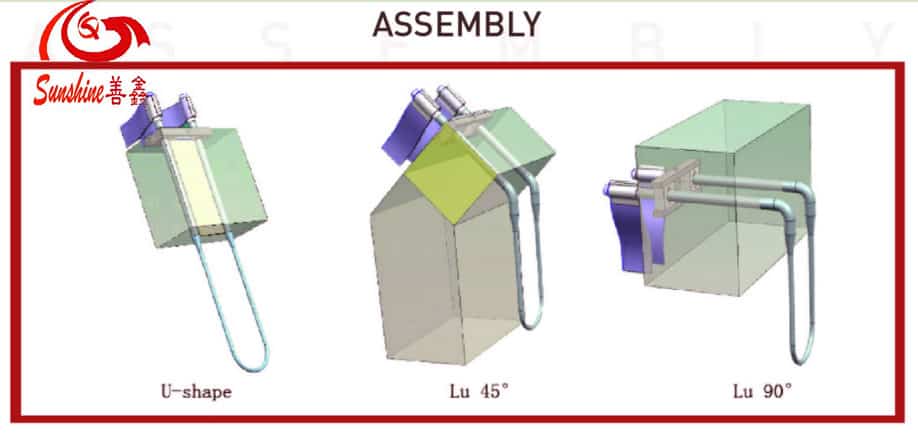

The assembly of U shape mosi2 heating element

- Transition section (g) should be inserted inside the furnace, to avoid the case that heat can not emit and resulting in damage of the transition section.

- When installing, it is necessary to keep certain distance between the U shape mosi2 heating element and furnace bottom (h).

- Make sure a reasonable distance between the U shape mosi2 heating element and furnace wall.

- The suggest surface load of 1700 type U shape mosi2 heating element and furnace wall under 1300 C furnace temperature is below 13. 5w/cm3. The suggest surface load of 1800 type U shape mosi2 heating element under 1600℃ furnace temperature is below 11. 5w/cm2. And the suggest surface load of 1850 type products under 1720 C furnace temperature is below 12 w/cm2.