Why M type silicon carbide heating element

M type silicon carbide heating Elements look like the letter “M”, also known as W-type silicon carbide heating elements, there are three heating units.

How to install M type silicon carbide heating element?

The two cold ends of the M-type Globar Silicon Carbide heating element and the heating area form a right-angled structure, which can be installed on the furnace roof or the side of the furnace. It is suitable for furnaces with narrow spaces or furnaces that are not convenient for wiring at both ends.

In addition, for furnaces that are too wide or too high, the M-shaped rods can be arranged on one side of the furnace, so that the inner surface of the furnace is divided into multiple temperature zones to control and improve the uniformity of the furnace temperature.

The application of M type Silicon Carbide heating element

Three phase Globar silicon carbide heating element performers in float glass production. M type Globar sic heating elements are comprised of hight -purity, high-density, silicon carbide grains that are self bonded through redry.

Globar Silicon carbide heating elements are designed to be utilized in float baths for the manufacture of soda lime flat glass architectural, automotive and solar-glass applications, Silca type W-Three phase Globar silicon carbide heating element float glass heating elements have recorded campaign lengths up to 22 years.

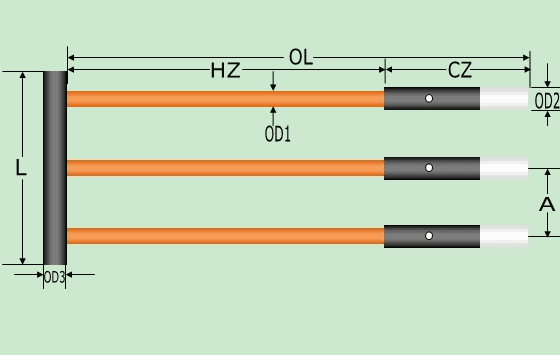

When you inquiry, Please inform us

- Outer diameter (OD)

- Length of Hot zone (HZ)

- Cold end length(CZ)

- Length of Overall (OL)

- Vottage and Wattage

- Quantity