General introduction

ED type sic heating elements(also called RR type sic heating elements) is a straight rod type resistance heating element made of green silicon carbide as the main raw material, through hydraulic preliminary forming, baking, sintering and recrystallization, hot and cold end resistance cooperation and 2400 ℃ secondary sintering according to a certain proportion.

The temperature of ED type sic heating elements can reach 1450 ℃. When the temperature reaches 1300 ℃, a dense glass oxide film can be formed on the surface of the rod, which prevents itself from being oxidized, thus greatly prolonging the service life of the rod.

| Power Source | Electric |

| Weight | According to size |

| Application | Industrial Heating Parts |

| Classification | Furnace heater |

| flexure strength | 50MPa |

| porosity | 23% |

| Heat conductivity (hot end) | 12-18W/m+℃ at 1000℃ |

| specific heat | 1.0 kj/kg+℃ at 25℃-1300℃ |

| Specific resistance (hot end) | 0.08Ω cm at 1000℃ |

| The coefficient of thermal expansion | 4.5X10-6 |

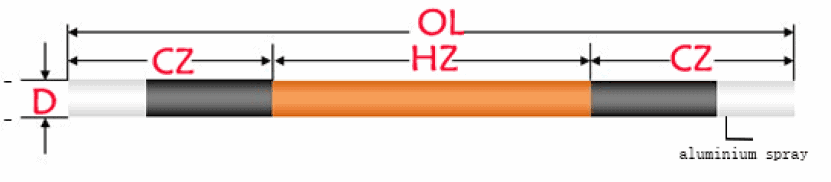

Model number and reference data about ED type sic heating elements

| Outer Diameter (OD,mm) | Hot zone (HZ, mm) | Cold zone (CZ,mm) | Overall length (OL,mm) | Range of resistance (ohms) |

| 8 | 100-300 | 60-200 | 240-700 | 2.1-8.6 |

| 12 | 100-400 | 100-350 | 300-1100 | 0.8-5_8 |

| 14 | 100-500 | 150-350 | 400-1200 | 0.7-5.6 |

| 16 | 200-600 | 200-350 | 600-1300 | 0.7-4.4 |

| 18 | 200-800 | 200-400 | 600-1600 | 0.7-5.8 |

| 20 | 200-800 | 250-600 | 700-2000 | 0.6-6.0 |

| 25 | 200-1200 | 250-700 | 700-2600 | 0.4-5.0 |

| 30 | 300-2000 | 250-800 | 800-3600 | 0.4-4.0 |

| 35 | 400-2000 | 250-800 | 900-3600 | 0.5-3.6 |

| 40 | 500-2700 | 250-800 | 1000-4300 | 0.5-3.4 |

| 45 | 500-3000 | 250-750 | 1000-4500 | 0.3-3.0 |

| 50 | 600-2500 | 300-750 | 1200-4000 | 0.3-2.5 |

| 54 | 600-2500 | 300-750 | 1200-4000 | 0.3-3.0 |

Instanllation and Operation of ED type sic heating elements

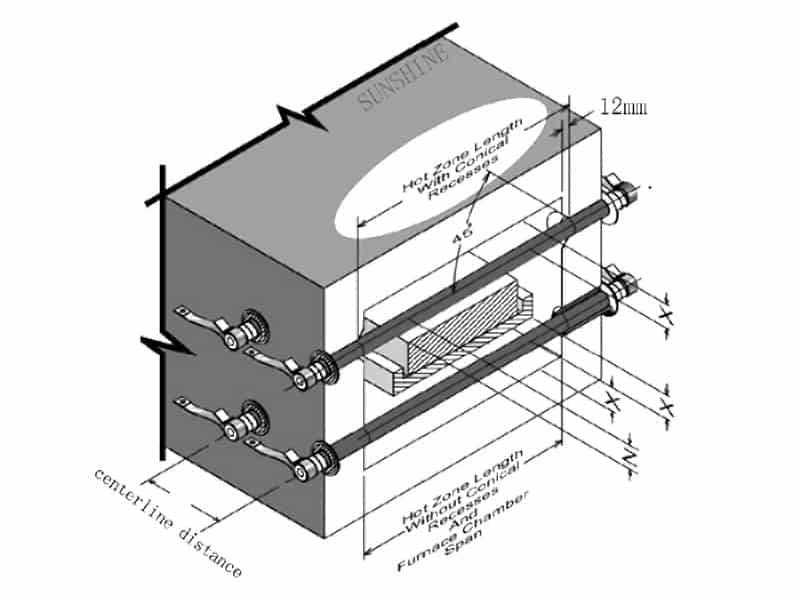

The application of ED type sic heating elements

ED type(also called RR type)is an alternative product of thick-end silicon carbide rods.

These two types of heating elements are used in applications ranging in temperature from 600°C up to 1500°C in both air and controlled atmosphere. The type of atmosphere used will determine the maximum recommended element temperature. ED type sic heating elements.may be mounted either vertically or horizontally, and as the material remains rigid, even at the maximum operating temperatures, no special supports are required.

It is commonly used in rare earth phosphors, electronics, magnetic materials, powder metallurgy, precision casting and other industries as a pusher furnace, Mesh belt furnace, trolley furnace, box furnace heating elements.

The advantages of ED(RR) type SiC heating elements

The equal diameter ED type sic heating elements is a non-metallic silicon carbide product obtained by recrystallization of high purity silicon carbide using a unique high temperature sintering technology. In the process of using, it generally has the following advantages:

- Equal diameter silicon carbon rod has high mechanical strength, bending strength up to 100-120MPa.

- The high surface temperature can reach 1500 degrees.

- high infrared emissivity, equal diameter silicon carbon rod is 5-10 times of ordinary nickel chromium wire.

- Long service life, simple installation and maintenance.

- equal diameter silicon carbon rod has strong oxidation resistance, corrosion resistance, and excellent heat shock resistance.

In addition to the above advantages, ED type sic heating elements also have high mechanical strength, strong earthquake resistance, good chemical stability, and easy installation characteristics, is a durable quality environmental protection products.

ED type sic heating elements are substitute products of coarse end type silicon carbon rod, with small end resistance, long service life, energy saving and other advantages. Under the same specifications, the power of the equal diameter is larger than DB type SiC heating elements, the service time is long, and the corrosion resistance is strong.

When you inquiry, Please inform us:

- Outer diameter (OD)

- Length of Hot zone (HZ)

- Cold end length(CZ)

- Length of Overall (OL)

- Vottage and Wattage

- Quantity