What is straight shape mosi2 heating element?

Straight shape mosi2 heating elements and DB type sic heating elements are similar in appearance, both are linear in shape, but they are made of different materials.

The straight shape mosi2 heating element is made of molybdenum disilicide and the DB type sic heating element is made of self-bonded silicon carbide.

Straight shage mosi2 heating element is also called I type mosi2 heating element

| Size | Customized |

| Supply Ability | 5000 Piece/Pieces per Week for straight shape MoSi2 heating element |

| Experience in Making | 20 years Heater Element |

| Volume Density | 5.8~6.2g/CM3 |

| Bending Strength | 15-25kg/cm3 |

| Vickers Hardness | (HV)570kg/mm2 |

| Porosity | 7.40% |

| Water absorption | 1.20% |

| Heating Elongation Rate | 4% |

| Packing | Cartoon box inside,Polyfoam filled, Wooden box outside |

| After-sales Service Provided | Overseas service center available |

Specification

Manufactured to industry established diameters and resistance values in the following diameters: 3/6, 4/9, 6/12, 9/18 and 12/24 mm.

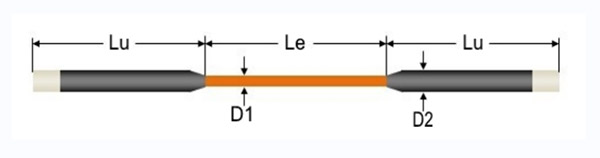

Straight shape MoSi2 heating element length: Lu length from 150 to 1000mm, Le length from 150 to 1500mm, customized is available.

Straight shape MoSi2 heating element operation temperature: From 500C to 1750℃.Max temperature can up to 1900℃

Straight shape mosi2 heating element eference data

| Diameter(mm) φd(hot zone)/ φc (cold zone) | shape | length(mm) Le(hotzone)/Lu(cold zone) | a(mm) | g(mm) | f(mm) | h(mm) | n(mm) | ||

| Standard | Minimum | Standard | Minimum | ||||||

| 3/6 | U shape,L shape,W shape or customized | customized | 25 | 12 | 15 | 30 | 10 | 40 | 35 |

| 4/9 | U shape,L shape,W shape or customized | customized | 25 | 15 | 20 | 30 | 10 | 50 | 45 |

| 6/12 | U shape,L shape,W shape or customized | customize | 50 | 25 | 25 | 45 | 15 | 90 | 70 |

| 9/18 | U shape,L shape,W shape or customized | customized | 60 | 35 | 32 | 75 | 20 | 135 | 110 |

| 12/24 | U shape,L shape,W shape or customized | customized | 80 | 50 | 40 | 100 | 35 | / | / |

The advantage of straight shape mosi2 heating element

1.Elements have the capabilities to resistance to oxidation and automatically repair, suitable for continued using in any kinds of oxidizing atmospheres.

2.Elements are shaped in hot-working process, which keeps the base material in good tenacity and plasticity at high temperatures.

3. The geometrical figure, standard and dimension is canonical, may produce any special shape and any dimension to meet the customer requirement.

4.Because of the special technology, welding spot is fast and shock resistance, which dramatically reduced the damaged probability of welding spot by electric current, as well as transit and installation.

5.High density of Spark MoSi2 Heating Elements increases its electrical conductivity.

6. The characters of faster warming and power consumption low, which reduce production cost.

Good appearance quality and tenacity, high mechanical strength.

7.Adopt special technology, heaters come wit.

The replacement of mosi2 heating element

If there is a damaged part found in the process of operation, the first thing you should do is determine its location and get all the combination elements ready. After that, you should separate the wire the damaged element clipped to from the screw which is connected to the generatrix. Then remove the remained refractory wool and pull out the refractory stoppers. Insert the new combination elements into the furnace from its roof. Connect all the wires and get the refractory wool filled, and finally raise the temperature.

Straight shape mosi2 heating element are defined by:

- Element grade 1700 Grade, 1800 Grade,1850 Grade, 1900 Grade or Super pure Type

- Heating zone diameter “d”, mm

- Terminal diameter “c”, mm

- Terminal length “Lu”, mm

- Heating zone length “Le”, mm

Example: 1800 Grade,9/18, Lu = 320 mm

Sizes Available

Le = 510 mm