What is SGR type Double Spiral Silicon Carbide Heating Element?

SGR type Double Spiral Silicon Carbide Heating Element similarly to Single spiral type.

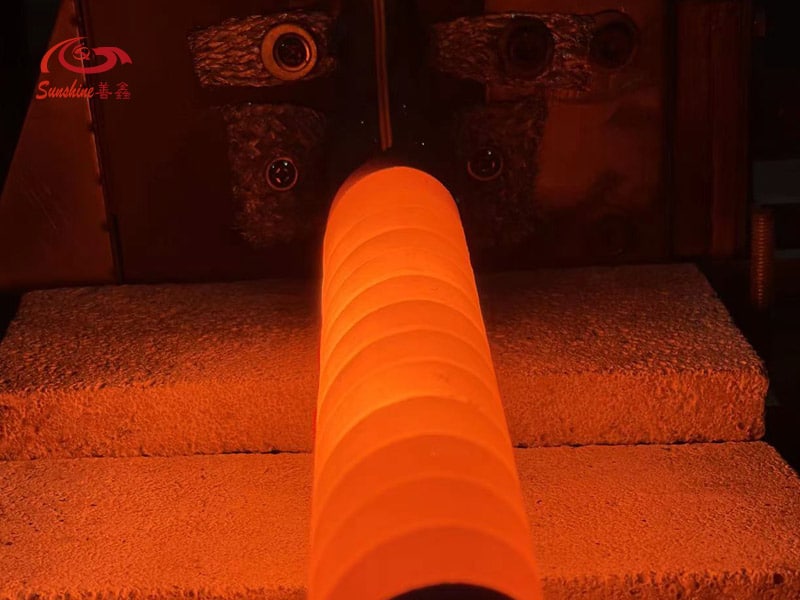

SGR type Double Spiral Silicon Carbide Heating Element is a tubular element with a spiral-grooved heating section, and as a major characteristic, both electrical connections are found at one end only.Sunshie double spiral silicon carbide heating element is crafted from special materials. It features a hot zone density of 2.8 g/cm³ and can operate at temperatures up to 1625°C, ensuring a very long working life. One end of the wire is designed for easy installation.

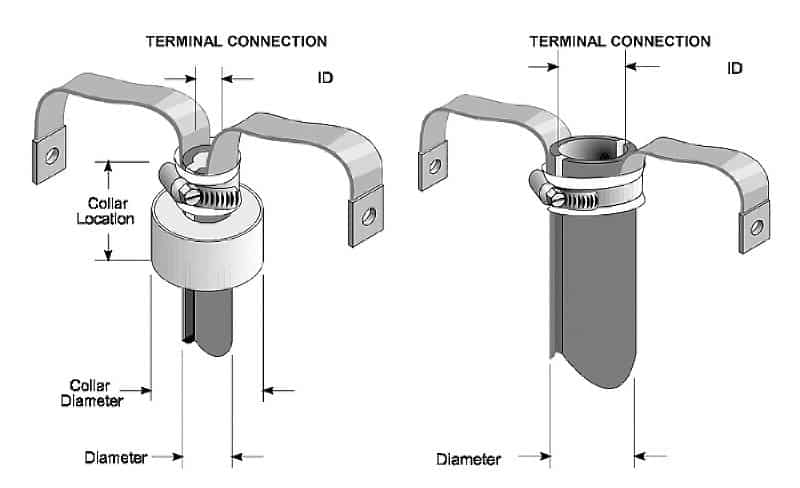

Double spiral Double Spiral Silicon Carbide Heating Element(SGR type SiC Heater Element) is a kind of electric heating element with one end connection. The heating end is spiral, the upper and lower parts are cold ends, the upper part is conductive end, and the lower part is supporting end.

The cold end is divided into two parts by a gap cut vertically from the middle, which is connected to the positive and negative terminals of the power supply.

| Production process | Made into blank, silicided under high temperature and re-crystallized. | |

| Weight | According to size | |

| Classification | Furnace heater | |

| Packing | Cartoon box inside, Polyfoam filled, Wooden box outside | |

| After-sales Service Provided | Overseas service center available | |

| Power Source | Electric | |

| Material | Above 99% Silicon carbide, Silicon Carbide (SiC) | |

| Also called | Sic resistance / sic heater / silicon carbide heater rod | |

| Flexure strength | 98MPa | |

| Porosity | 5% | |

| Heat conductivity (hot end) | 16-21W/m+℃ at 1000℃ | |

| Specific heat | 1.0 kj/kg+℃ at 25℃-1300℃ | |

| Specific resistance (hot end) | 0.016Ω cm at 1000℃ | |

| The coefficient of thermal expansion | 4.5×10-6 |

SGR type Double Spiral Silicon Carbide Heating Element is energy-conserving, convenient and easy to install due to the same-end terminal structure.

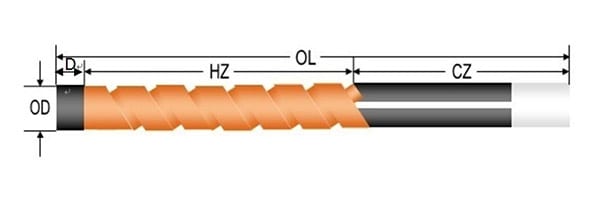

Model number and reference data for SGR type Double Spiral Silicon Carbide Heating Element

| SCR Type Double Spiral Silicon Carbide Heating Element | ||||

| Dia(mm) | Nominal Loading(at 1050℃) | |||

| Hot Zone | Cold End | |||

| Ω/mm | W/mm | Ω/mm | W/mm | |

| 18.0 | 0.02158 | 8.48 | 0.00430 | 1.70 |

| 200 | 0.02302 | 9.42 | 0.00384 | 1.6 |

| 25.0 | 0.01969 | 11.78 | 0.00328 | 1.75 |

| 30 | 0.01523 | 14.13 | 0.00190 | 1.75 |

| 31.7 | 0.01341 | 14.93 | 0.00152 | 1.85 |

| 35.0 | 0.01224 | 16.49 | 0.00150 | 2 |

| 38.1 | 0.01103 | 17.95 | 0.00116 | 2 |

| 40.0 | 0.00905 | 18.84 | 0.00100 | 2.10 |

| 44.4 | 0.00960 | 20.91 | 0.00079 | 2.10 |

| 54.0 | 0.00636 | 25.43 | 0.00073 | 2.30 |

SGR type Double Spiral Silicon Carbide Heating Element regular size

| SGR TYPE | ||||||||

| Φ(mm) | OL(mm) | |||||||

| HEATER | Φ16 | 30+10-5 | ||||||

| >Φ20 | 50+20-10 | |||||||

| SIZE | DIAMETER(mm) | HZ | CZ | OL | SURFACE | RESISTANCE | ||

| mm | mm | mm | cm² | VOLT | POWER | ±20% | ||

| SGR16*100*150 | 16 | 100 | 150 | 250 | 50 | 61 | 940 | 3.96 |

| SGR16*100*200 | 100 | 200 | 300 | 50 | 69 | 1060 | 4.49 | |

| SGR16*150*150 | 150 | 150 | 300 | 75 | 84 | 1290 | 5.47 | |

| SGR16*150*250 | 150 | 250 | 400 | 75 | 99 | 1520 | 6.45 | |

| SGR16*200*200 | 200 | 200 | 400 | 100 | 113 | 1740 | 7.34 | |

| SGR16*250*200 | 250 | 200 | 450 | 125 | 135 | 2080 | 8.76 | |

| SGR20*100*150 | 20 | 100 | 150 | 250 | 62 | 58 | 1110 | 3.03 |

| SGR20*100*250 | 100 | 250 | 350 | 62 | 72 | 1380 | 3.76 | |

| SGR20*150*200 | 150 | 200 | 350 | 94 | 87 | 1670 | 4.53 | |

| SGR20*200*200 | 200 | 200 | 400 | 125 | 109 | 2090 | 5.68 | |

| SGR20*250*150 | 250 | 150 | 400 | 157 | 124 | 2380 | 6.46 | |

| SGR20*250*250 | 250 | 250 | 500 | 157 | 138 | 2650 | 7.19 | |

| SGR20*300*250 | 300 | 250 | 550 | 188 | 160 | 3070 | 8.34 | |

| SGR25*150*200 | 25 | 150 | 200 | 350 | 117 | 87 | 2000 | 3.78 |

| SGR25*200*200 | 200 | 200 | 400 | 157 | 110 | 2530 | 4.78 | |

| SGR25*200*300 | 200 | 300 | 500 | 157 | 121 | 2780 | 5.27 | |

| SGR25*300*300 | 300 | 300 | 600 | 235 | 167 | 3840 | 7.26 | |

| SGR25*300*400 | 300 | 400 | 700 | 235 | 179 | 4120 | 7.78 | |

| SGR25*350*300 | 350 | 300 | 650 | 274 | 191 | 4390 | 8.31 | |

| SGR25*400*300 | 400 | 300 | 700 | 314 | 214 | 4920 | 9.31 | |

| SGR30*200*200 | 30 | 200 | 200 | 400 | 188 | 190 | 2790 | 2.9 |

| SGR30*250*200 | 250 | 200 | 450 | 235 | 111 | 3440 | 3.58 | |

| SGR30*300*300 | 300 | 300 | 600 | 282 | 132 | 4090 | 4.26 | |

| SGR30*350*350 | 350 | 350 | 700 | 329 | 153 | 4740 | 4.94 | |

| SGR30*400*400 | 400 | 400 | 800 | 376 | 174 | 5390 | 5.62 | |

| SGR30*450*350 | 450 | 350 | 800 | 424 | 194 | 6010 | 6.26 | |

| SGR30*500*300 | 500 | 300 | 800 | 471 | 214 | 6630 | 6.91 | |

| SGR35*200*200 | 35 | 200 | 200 | 400 | 219 | 89 | 3260 | 2.43 |

| SGR35*250*200 | 250 | 200 | 450 | 274 | 109 | 3990 | 2.98 | |

| SGR35*300*300 | 300 | 300 | 600 | 329 | 130 | 4760 | 3.55 | |

| SGR35*400*300 | 400 | 300 | 700 | 439 | 171 | 6260 | 4.67 | |

| SGR35*450*350 | 450 | 350 | 800 | 494 | 191 | 6990 | 5.22 | |

| SGR35*500*300 | 500 | 300 | 800 | 549 | 211 | 7720 | 5.77 | |

| SGR40*200*200 | 40 | 200 | 200 | 400 | 251 | 86 | 3660 | 2.02 |

| SGR40*250*200 | 250 | 200 | 450 | 314 | 106 | 4510 | 2.49 | |

| SGR40*300*300 | 300 | 300 | 600 | 376 | 127 | 5400 | 2.99 | |

| SGR40*350*300 | 350 | 300 | 650 | 439 | 147 | 6250 | 3.46 | |

| SGR40*400*300 | 400 | 300 | 700 | 502 | 167 | 7100 | 3.93 | |

| SGR40*400*400 | 400 | 400 | 800 | 502 | 167 | 7100 | 3.93 | |

| SGR40*450*300 | 450 | 300 | 750 | 565 | 186 | 7910 | 4.37 | |

| SGR40*450*350 | 450 | 350 | 800 | 565 | 187 | 7950 | 4.4 | |

| SGR40*500*300 | 500 | 300 | 800 | 628 | 206 | 8760 | 4.84 | |

The Double Spiral Silicon Carbide Heating Element can be used in a variety of applications.

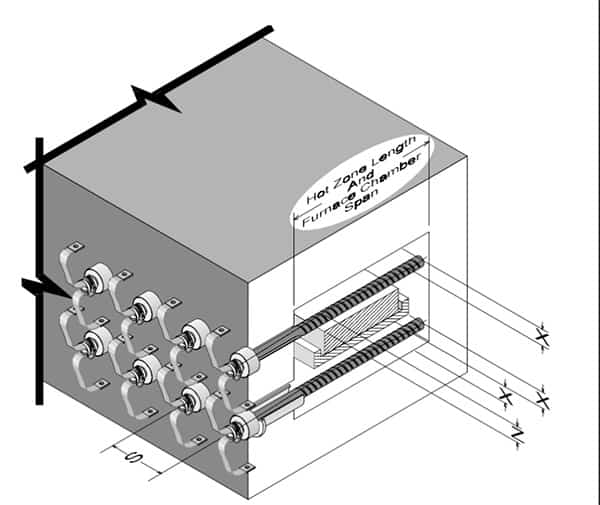

SGR elements are used in a wide variety of furnace applications, from small laboratory furnaces to large industrial heating processes, in different atmospheres and temperature ranges.

Used in dental furnaces

Most zirconia materials require sintering at high temperatures of 1450–1550°C for two hours or more. As a common electric heating element in zirconia sintering furnaces, silicon carbide rods are ideal for this process. They can be used to heat zirconia in an open crucible without a cover, which eliminates the need for a double atmosphere inside the crucible and enhances the accuracy of sintering. This approach avoids the complications of a second heating environment. Additionally, silicon carbide rods can cool rapidly without damaging the components.

Installation and Operation of SGR type Double Spiral Silicon Carbide Heating Element

Two types of installation

SGR type SiC Heater Element can be mounted vertically or horizontally.

Mounting Horizontally

When mounting the SGR type SiC Heater Element horizontally, the hot end does not need to be supported, the slot in the terminal end should not come in contact with the insulation in the wall of the furnace or kiln.

This is most easily accomplished by placing the slot in a horizontal position. The terminal holes should also be 10% larger than the diameter of the element.

Extreme caution should be used when mounting to ensure that the SGR type SiC heating elements are not placed in tension.

There should be adequate freedom to allow for the furnace and SGR type SiC heating elements to expand and contract independently.

Location of installation

SGR type SiC heater elements should have their heating sections centered in the furnace chamber so that no portion of the heating section extends into the furnace wall.

A conical or truncated cone shaped recess 1/2 inch (13mm) deep is sometimes located on the interior wall where the SGR type SiC heating elements passes through. This allows the hot zone to radiate properly and helps maintain a uniform emperature in the kiln.

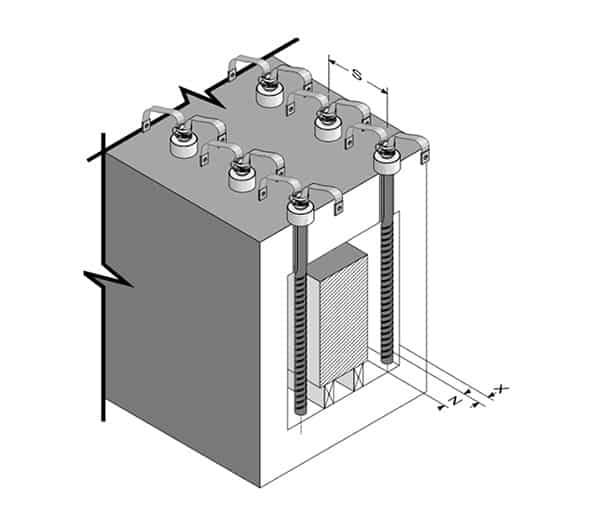

Recommended SGR type Double Spiral Silicon Carbide Heating Element spacing

X = 2 × element diameter is the minimum,

1.5 × element diameter is the absolute minimum and requires a reduced element surface watt loading.

Z = S ÷ 1.41 minimum for stationary loads

Z = S ÷ 1.73 minimum for moving loads

S = 2 × element diameters minimum

X – distance from the centerline of element to any reflecting surface, such as a refractory wall or centerline of an adjacent element

The advantages of SGR type Double Spiral Silicon Carbide Heating Element

Double spiral SiC Heater Element has a characteristic of current heating, heating speed fast, uniform temperature field; The normal temperature in oxidation atmosphere can reach 1450℃, and the continuous use can reach 2000 hours.

And it has good chemical stability, high temperature resistance, oxidation resistance, corrosion resistance.

The conductive end of the cold end of the double spiral silicon carbon rod is evenly sprayed with aluminum layer, which greatly improves the conductive property.

Connection method for SGR type Double Spiral Silicon Carbide Heating Element

Double spiral SiC Heater Element is suitable for wiring on one side of electric furnace. The diameter and length of cold and hot end of equal diameter silicon carbide rod can be selected according to the requirements of electric furnace structure, temperature and power.

The single ended connection of SGR type sic heater element makes them ideally suited to various applications where standard elements cannot conveniently be used, such as where access would be difficult, or in any case where single ended connections are essential.

Production process

In the production process of double spiral silicon carbon rod, special technology is arranged to strengthen and transform the rod body, so that different specific production materials and layer technology are added to the element body according to the different use environment (or acid or alkaline) to improve the purpose of resistance and service life.

Video

SGR type Double Spiral Silicon Carbide Heating Element and accessories

The elements allow great freedom in furnace design which, combined with simple installation and long operating life.

This makes them the preferred choice in many applications including: Glass, ceramics, electronics and metal industries and also for research and development.

When you inquiry, Please inform us

- Outer diameter (OD)

- Length of Hot zone (HZ)

- Cold end length(CZ)

- Length of Overall (OL)

- Vottage and Wattage

- Quantity