What is rotary tube furnace?

Rotary tube furnace is an electric heat treatment furnace that rotates during the heat treatment process. It is suitable for processes with short heating times and continuous operation, and is also used in laboratories for the treatment of bulk materials.

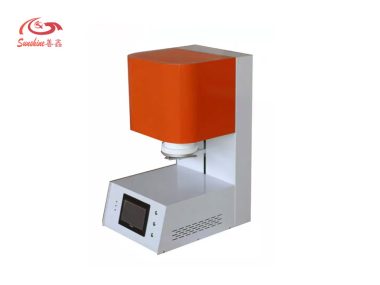

High Temperature Rotary Tube Furnace, 1200℃ Rotating Tube Furnace, 3-7 RPM is designed to heat loose materials for physiochemical processing, and they are classified depending on their heat-exchange method: parallel or opposing gas flow, and their method of energy transfer: direct, indirect or combined.

This rotary tube furnace is designed for continuous materials processing as it applies heat to the sample in thermal control zones (multi zones is also available). it can burn pulverized, solid, gaseous, or liquid fuel into its working section, and then the heating gases created flow towards the sample.

Our rotary tube furnace is mainly used for calcining inorganic compounds with better uniformity, especially excellent for preparing Li-Ion battery cathode materials with a conductive coating, such as LiFePO3, LiMnNiO3, etc in R&D Laboratory.

Rotary Tube Furnace Features

Max temperature 1200 ℃

50 segments programmable and PID auto control

Heating rate: 0~20 ℃/min.

Temperature accuracy: ±1 ℃

Upper open furnace cover design for real-time observation of heated materials.

Furnace tilt angle 0 – 30℃ variable, it’s convenient for loading and unloading material.

Tube rotating Speed 3 – 7 RPM variable ( reversible), and there are 3 quartz lifting plates on the inner wall of the tube. When rotating, the material is fully turned over and evenly heated.

It has safe operation functions such as opening and closing power, over temperature alarm and leakage protection.