Proper installation and maintenance of Mosi2 heating elements are critical steps in ensuring their longevity and proper use.

During installation, it is important to ensure that the components are sized for the application and are securely mounted to prevent damage or failure. Additionally, proper wiring and insulation are critical to safety and performance.

There are usually several ways to install:

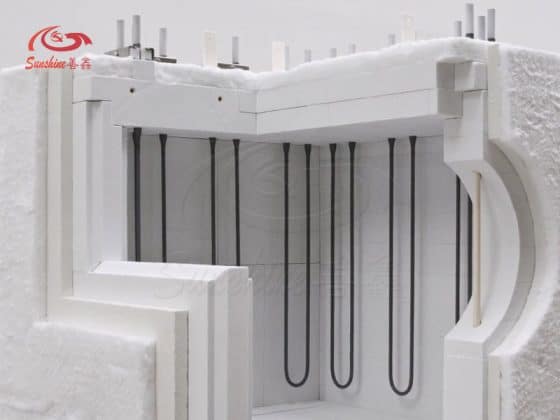

Vertically Hanging

Under normal temperature, MoSi2 element is very brittleness, while under high temperature it is plasticity. So, the better way for installation if the U Shape element is to hang it vertically, to the furnace top through the support clamping chuck H.

The aim of such way is to avoid putting the mechanical stress directly to the element heat-generating end, or the element will easily be broken.

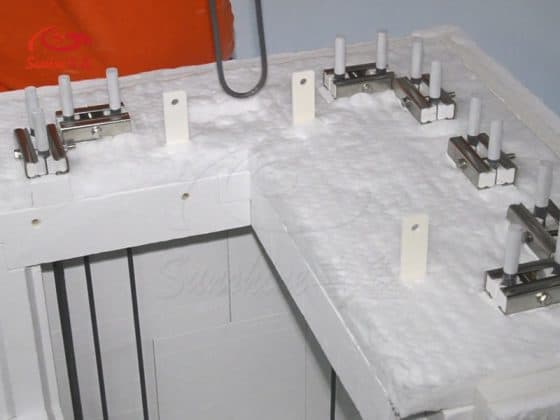

Support Clamp

Support clamp are applied to 9/18 and 6/12 two kinds of elements respectively. The support clamp supports the whole weight of the element and the position of the element is also determined by it.

Therefore, it must be installed carefully to assure that the element it vertically hung. In order to prevent the element from being over heated locally, the taper part of the element lower end must put into the furnace chamber.

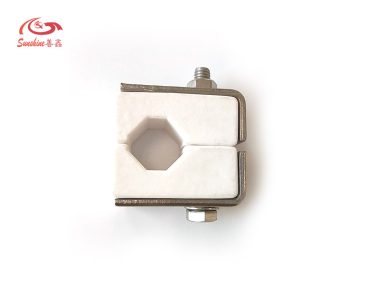

Wire clip

The wire connection clamp connecting MoSi2 element is made of aluminum woven wire or multilayer aluninum foil. The steel plate outside it only acts as a clamp and isn’t used for electric conduction.

For 6/12 element, single rowing wire is used,and for 9/18element,double-rowing wire is used,the end of the lead wire should be a little larger than the linear distance between the element and bus.

The brittleness of MoSi2 heating element is relative more under the usual temperature; it also has plasticity under the high temperature. So you had better hang and erect vertically the “U”-shape element. If you need to erect it horizontally, please choose a support of high-temperature insulating materials. The cone-part of the element must extend inside the furnace.

At first the fixture of MoSi2 power connector can’t be screwed too tightly.When temperature of the element is going up, please twist it tightly again, so the element is not easily broken.

For maintenance, regular inspections should be performed to check for signs of wear or damage, such as cracking or deformation. Cleaning should be done carefully to avoid damaging the element, using appropriate tools and solutions.

In addition, any issues with power supply or temperature control should be promptly addressed to prevent damage to the element.

(Our suggestion: please choose the specialize power connector provided by our company)

The furnace top must be a good function of heat-preservation. In general, the temperature of furnace top can’t be over 300C. The voltage should be low 0.1 between the power connector and the element.

In order to avoid radiating heat to pass the connector, the distance is not less than 50mm between the low end of connector and the upside of the ceramic brick. The Dia.6 element can’t be used of 170A for a long time. The Dia. 9 element can’t be used of 300A for a long time.