The molybdenum disilicide softens at temperatures over 1200ºC therefore will elongate or stretch when suspended vertically. The heating element can be destroyed if it comes in contact with the floor of the furnace while hot and under power.

To allow for the increase in length and keep it a safe distance above the floor, the hot zone (Le) must be shorter than the heated chamber height.

To design the length of the hot zone, two steps are required:

Step1:

At the location in the furnace where the elements are suspended, determine the height (H) in millimeters.

Setp2:

The taper portion of the cold end (Lu) extends into he hot chamber. This cold end taper length varies with the diameter of the element. See Table D to obtain the taper length (g) inside the hot chamber.

To design the hot zone length (Le) use one of the following formulas:

for H less than 200mm Le=H-10-g

for H over 200mm Le=0.95H-g

H = height of furnace in mm.

g = taper length in mm from Table D.

10 = minimum recommended vertical distance beneath the element in mm.

0.95 = shortening of the Le to allow for the element to stretch and be a safe distance above the floor.

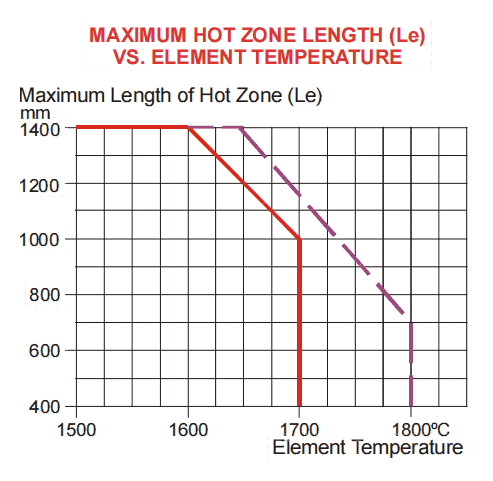

The following are maximum length limitations on the hot sections:

3/6 and 4/9 maximum Le = 400mm

6/12, 9/18 and 12/24 maximum Le = 1400mm

The 6/12, 9/18 and 12/24 maximum lengths are reduced based on element temperatures over 1600ºC