What is U type silicon carbide heating element?

U type silicon carbide heating element consists of two Silicon Carbide legs with equal diameter. Each leg is divided into two parts, hot zone and cold zone with a joint. Resistances of both legs are equal to ensure a uniform performance. Both shanks are joined with a crossbar made of low resistance.

U type silicon carbide heating element model number and reference data

| Dia(mm) | Nominal Loading(at 1050℃) | |||

| Hot Zone | Cold End | |||

| Ω/mm | W/mm | Ω/mm | W/mm | |

| 12 | 0.01684 | 11.3 | 0.0011 | 0.6 |

| 14 | 0.0136 | 13.19 | 0.0009 | 0.8 |

| 16 | 0.00993 | 15.07 | 0.0008 | 1 |

| 20 | 0.00652 | 18.84 | 0.0004 | 1.1 |

| 25 | 0.00432 | 23.55 | 0.0003 | 1.2 |

| 30 | 0.00298 | 28.26 | 0.0002 | 1.3 |

| 31.7 | 0.00256 | 29.86 | 0.00013 | 1.4 |

| 35 | 0.00271 | 32.97 | 0.00015 | 1.5 |

| 38.1 | 0.00173 | 35.89 | 0.00009 | 1.6 |

| 40 | 0.00212 | 37.68 | 0.0001 | 1.7 |

| 44.4 | 0.00114 | 41.82 | 0.00007 | 1.8 |

Selection of power supply U type silicon carbide heating element

U type silicon carbide heating element can work with 220V and 380V. when using 220V,we often choose series or parallel,When used in series, the resistance of the two silicon rods should be the same.

If they are different, the service life will be shortened.If the resistance is inconsistent, one resistance is large, another resistance is small, the service life will be shortened. In the 380V circuit,we often choose star connection and triangle connection.

Connection mode of U type silicon carbide heating element

Small electric furnace uses star connection, the method is simple and convenient, large electric furnace uses triangle connection. Generally speaking according to the furnace power we choose the electric furnace heating element connection method.

Application of U type silicon carbide heating element

U type silicon carbide heating element is often used in kiln requiring single end connection, and often used in push plate furnace, trolley furnace, box furnace and other periodic electric furnace.

The advantages of U type silicon carbide heating element

U type silicon carbide heating element is made of two equal diameter silicon carbon with a common cold end, U-type silicon carbon rod can be connected to one end of the kiln, the surface temperature of the hot zone is 1500°C.It is mainly used for the high temperature furnace and high temperature kiln, its characteristics are energy-saving and long service life.

| Classification | Furnace heater | |

| Power Source | Electric | |

| Production process | Made into blank, silicided under high temperature and re-crystallized. | |

| Weight | According to size | |

| Also called | Sic resistance / sic heater/silicon carbide heater rod | |

| SiC Content | Above 99% | |

| Material | Silicon carbide, Silicon Carbide (SiC) | |

| Flexure strength | 50MPa | |

| Porosity | 23% | |

| Heat conductivity (hot end) | 12-18W/m+℃ at 1000℃ | |

| Specific heat | 1.0 kj/kg+℃ at 25℃-1300℃ | |

| Specific resistance (hot end) | 0.08Ω cm at 1000℃ | |

| The coefficient of thermal expansion | 4.5×10-6 |

Video

Design suggestion of U type silicon carbide heating element

- The length of the heating part of the silicon carbide rod shall be equal to the total width of the furnace. If the heating part is inserted into the furnace wall, it is very easy to ablate the furnace wall.

- The length of the cold zone of the silicon carbide rod shall be equal to the thickness of the furnace wall plus the length of the cold zone extension length out of furnace wall. General speaking cold zone extension length is 50 ~ 150mm, it is convenient to make cold zone and accessories to connect.

- The nominal diameter of the furnace with silicon carbon rod should be 1.4 ~ 1.6 times of the diameter of the cold end. If the furnace hole is too small or the filling material in the hole is too tight, the continuous high temperature will prevent the silicon carbon rod from freely expanding, resulting in broken rod. When assembled, the silicon carbon rod should be able to rotate 360 degrees at will.

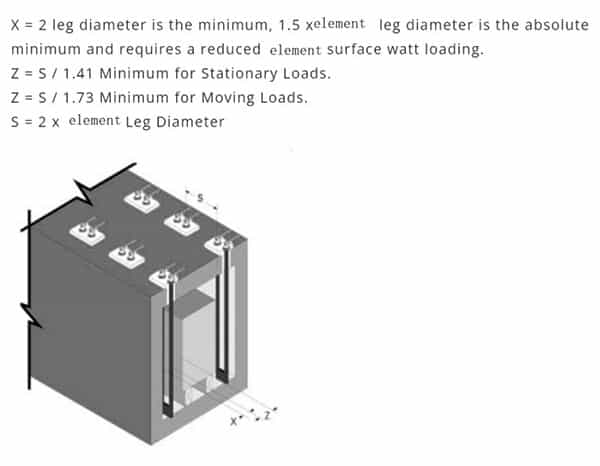

- The spacing between the silicon carbon rod and the heated material or the furnace wall should be greater than or equal to 3 times the outer diameter of the heating part. The center distance between the silicon carbon rods should not be less than 4 times the outer diameter of the heating part.

x=2 leg diameter is the minimum, 1.5 × element leg diameter is the absolute minimum and requires a reduced element surface watt loading.

Z=S/1.41 Minimum for Stationary Loads.

Z=S/1.73 Minimum for Moving Loads.

S=2 × element Leg Diameter

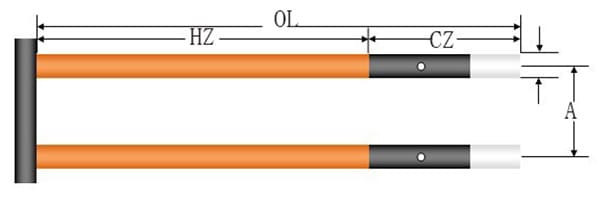

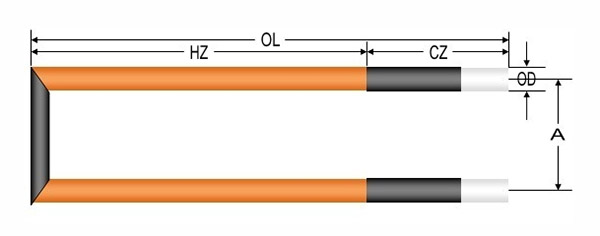

When you inquiry, Please inform us

- Outer diameter (OD)

- Length of Hot zone (HZ)

- Cold end length(CZ)

- Length of Overall (OL)

- center distance (A)

- Vottage and Wattage

- Quantity