1.The molybdenum disilicide (mosi2) heating element should be installed vertically on the top of the furnace, and the element should be fixed in place by the support clamp to avoid mechanical stress and deformation.

2. The lining material should use corundum brick, and the mass fraction of Fe2O3 should be less than 1%, so as not to react with the protective film of the molybdenum disilicide (mosi2) heating element.

3.The cold end part of molybdenum disilicide (mosi2) heating element should be exposed outside the top of the furnace by 75mm, the junction of the cone of the heating part should be about 25mm-30mm away from the furnace wall, and the lower end of the heating part to the bottom of the furnace should not be less than 50mm.

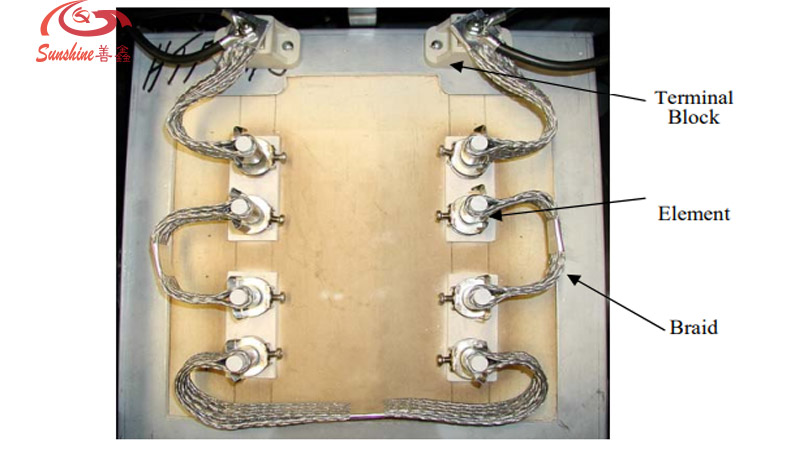

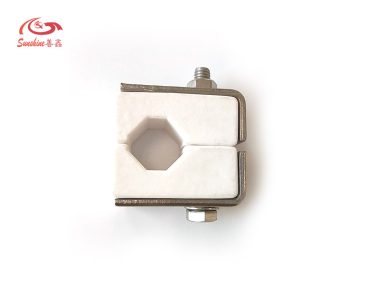

4.The wire clamp should use aluminum braided wire or multi-layer aluminum foil, and the outer steel plate only plays a clamping role and is not used for conduction. The temperature of the wire clamp part should generally not exceed 200°C.

5. In order to avoid loosening of asbestos clamp due to thermal expansion and contraction, refractory mortar mixed with water glass can be applied to the connection part to fix it firmly.

6 In order to avoid damage, generally diameter 6/12mm molybdenum disilicide (mosi2) heating element cannot be used for a long time at 170A, and diameter 9/18mm elements cannot be used for a long time at 300A.