1900 Grade mosi2 heating element can be used at 1850 degrees in air, the difference between 1900 Grade mosi2 heating element and 1700 Grade mosi2 heating element are:

The difference between grade 1900 mosi2 heating elements and grade 1700

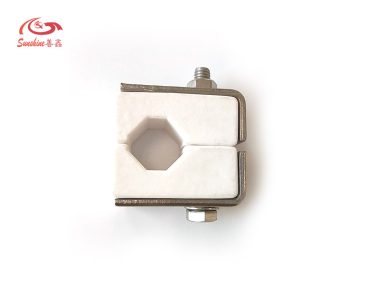

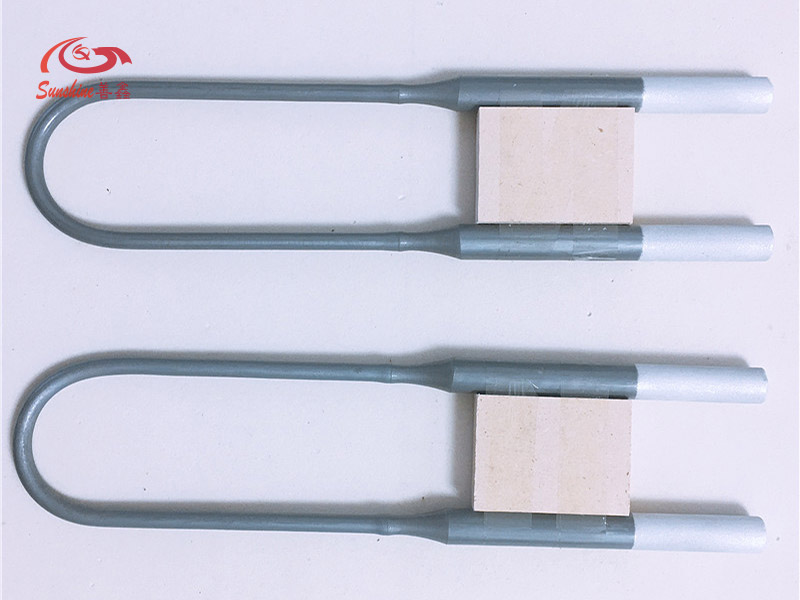

- (1) The welding joint of 1900 Grade is full, protruding, bulging, and there is no crack in the welding place, which is very different from 1700 Grade.

- (2) The surface of 1900 Grade mosi2 heating element is smoother and has metallic luster.

- (3) Higher density, compared with 1700 Grade, the same specification of 1900 Grade mosi2 heating element will be heavier.

- (4) The operating current and voltage of 1900 Grade mosi2 heating element are smaller than those of 1700 Grade, for the same element with hot end of Diameter 9mm, the operating current of 1900 degree is 220A, while that of 1700 degree is about 270A.

- (5) Température de fonctionnement plus élevée, de 200 degrés supérieure à celle de la qualité 1700.

- (6) More shapes can be made according to customer requirements.

- (7) 1900 Grade mosi2 heating element is more solid, and generally will not break during transportation and installation.

- (8) Longer service life of 1900 Grade mosi2 heating element, generally more than 18 months

Use the table to compare the differences between 1900 grade mosi2 heating elements and 1700 grade

| Caractéristique | 1900 Grade MOSI2 Heating Element | 1700 Grade MOSI2 Heating Element |

|---|---|---|

| Welding Joint | Full, protruding, bulging, no cracks | Different from 1900 Grade |

| Surface Appearance | Smoother, metallic luster | Different from 1900 Grade |

| Densité | Higher | Lower |

| Poids | Heavier for the same specification | Lighter for the same specification |

| Operating Current and Voltage | Smaller | Larger |

| Operating Current (Diameter 9mm, Hot End) | 220A | ~270A |

| Température de fonctionnement | 200 degrees higher than 1700 Grade | Lower than 1900 Grade |

| Shapes Available | More shapes possible based on customer needs | Limited shapes |

| Durability | More solid, less prone to breakage | Potentially prone to breakage during transport |

| Durée de vie | Generally exceeds 18 months | Varies, potentially shorter |