What is sisic reaction sintered silicon carbide?

Reaction sintering silicon carbide also called Reaction Bonded Silicon Carbide (RBSiC/SiSiC) is a densification process in which reactive liquid silicon or silicon alloy is infiltrated into a carbon-containing porous ceramic body to react to form silicon carbide, and then combined with the original silicon carbide particles to fill the remaining pores in the body.

Reaction sintered silicon carbide ceramics are a high-tech industrial ceramic material that possesses several unmatched properties, including high temperature strength, strong oxidation resistance, strong acid and alkali corrosion resistance, good thermal stability, high thermal conductivity, high wear resistance, and hardness second only to diamond. It is used a lot in mining industry, steel industry, coal processing industry, chemical industry, raw material-making industry, mechanical sealing, surface sandblasted treatment and reflector etc.

The technical data of sisic reaction-sintered silicon carbide:

| Properties | SiSiC |

| Bulk denstity SiC (Vo1%) | ≥85 |

| Bulk density (g/cm3) | 3.01 |

| Apparent porosity (%) | <0.1 |

| Modulus of rupture at 20℃ (Mpa) | 250 |

| Modulus of rupture at 1200℃ (Mpa) | 280 |

| Modulus of elasticity at 20℃ (Gpa) | 330 |

| Thermal Conductivity at 1200℃ (w.m-1.k-1) | 45 |

| Thermal expansion at 1200℃ (a×10-6/°C) | 4.5 |

| Thermal shock resistance at 1200℃ | Very good |

| Max.working temperature | 1380℃ |

The benefits of reaction-sintered silicon carbide

① Ultra-high hardness and superior wear resistance.

Thanks to the excellent hardness and abrasive resistance, Silicon Carbide tilecan effectively protect the part where need wear protection and prolong the service life of the equipment.

② Good wear resistance in sliding and abrasive environments

③ Corrosion resistance. Silicon carbide can tolerates a wide range of acids and alkalis.

④ High temperature resistance.

⑤ Good dimensional control of complex shapes.

⑥ High oxidation resistance.

⑦Low thermal expansion and high thermal conductivity leading to excellent thermal shock resistance.

Our company’s sisic reaction silicon carbide sintering products have the following types.

silicon carbide flame nozzle burner sleeves

One of the most popular products in the line of reaction sintered silicon carbide ceramics is silicon carbide flame nozzle burner sleeves. This product is specially designed for high-temperature kilns, such as roller kilns, tunnel kilns, and shuttle kilns. The silicon carbide flame nozzle burner sleeve has a high temperature strength that withstands temperatures without breaking or deformation. Moreover, it has rapid cooling and heat resistance, making it ideal for controlling temperature balance in the kiln. The flame nozzle burner sleeve has been widely used in the firing of porcelain, sanitary porcelain, architectural ceramics, and other high-temperature kilns.

silicon carbide desulfurization nozzles

Another significant application of reaction sintered silicon carbide ceramics is silicon carbide desulfurization nozzles used in thermal power plants, large boilers, and complete sets of desulfurization and dust removal devices. The localization of silicon carbide desulfurization nozzles has replaced imported products, making it a cost-effective solution with the same quality standards. Compared to other materials, the silicon carbide desulfurization nozzle has high strength, hardness, strong corrosion resistance, high temperature resistance, and is highly resistant to wear, making it ideal for use in harsh conditions. The commonly used types are mainly spiral nozzles and vortex nozzles.

Spiral silicon carbide desulfurization nozzles

Additionally, when it comes to desulfurization nozzles, the spiralsilicon carbide desulfurization nozzles stand out. The outer layer of the nozzle is spiral, which helps in providing a more even and effective cleaning. Moreover, the wear resistance of the nozzle is higher than other materials, reducing the need for maintenance. Furthermore, it has excellent performance in terms of corrosion, temperature resistance, and wear resistance, making it suitable for long-term use in harsh environments.

Silicon Carbide Wear Resistance

Silicon carbide wear resistance, it is synthesized from silicon carbide and carbon at high temperature,belongs to a kind of silicon carbide product.The silicon carbide wear resistance parts are widely used in mining,ore crushing,screening and transport of high wear,high corrosive fluids,also very suitable for mechanical products with high precision and sealing requirements,such as high pressure pump,magnetic pump etc.Is a new type of wear resistance material.Reaction-bonded silicon carbide wear resistance bushing has the characteristics of high hardness,high wear resistance,impact resistance,high temperature resistance,acid and alkali corrosion resistance and so on,and the actual service life is more than 6 times that of polyurethane.It is especially suitable for the operation of classification, concentration and dehydration of strong abrasive and coarse-grained materials,has been successfully applied in many mines.

Characteristics Silicon Carbide Wear Resistance

1.Liner engineering ceramics with high strength,high hardness,excellent wear and corrosion resistance.

2.Various processes:bonding,inlaying and socketing.

3.The ceramic is firmly bonded to the substrate and has good temperature resistance(-50℃ to 1350℃).

4.The surface of silicon carbide ceramic is smooth,it can prevent scale and dust.

5.High cost effective,simple process.

6.Easy to install.

We also have a variety of other reaction-sintered silicon carbide products, such as silicon carbide beam rollers

silicon carbide cold air pipes

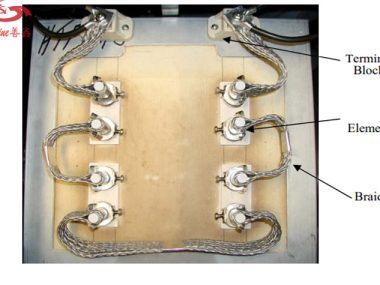

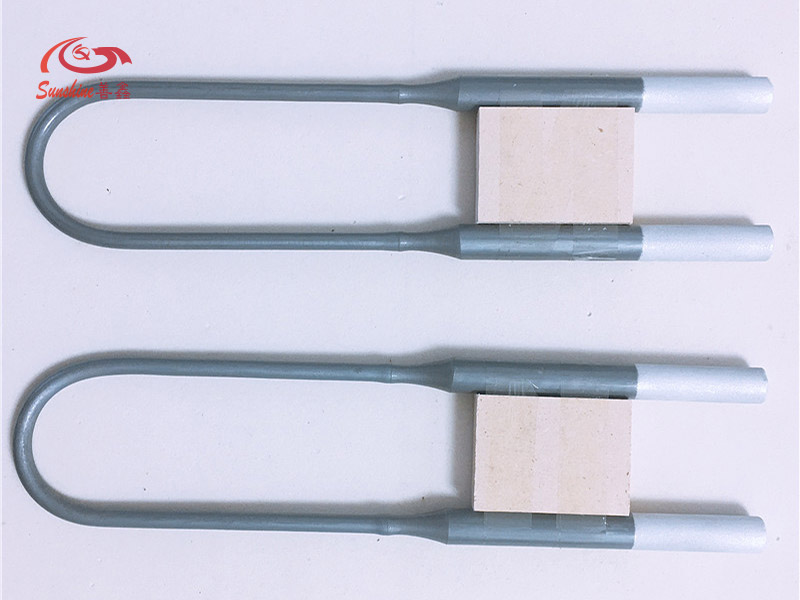

silicon carbide radiant tubes

silicon carbide preheating pipe air guide sleeves

silicon carbide sandblasting nozzles

silicon carbide wear-resistant linings, and more.

In conclusion, reaction sintered silicon carbide ceramics have found numerous applications in various industries and have become a popular choice due to their unmatched properties. Silicon carbide flame nozzle burner sleeves and silicon carbide desulfurization nozzles highlight just a few applications for this material. So, if you are looking for a material that with outstanding wear resistance, corrosion resistance, high temperature resistance, and extraordinary durability, reaction sintered silicon carbide ceramics should be a top consideration.