What is Recrystallized Silicon Carbide (RSIC) ceramic?

Recrystallized Silicon Carbide (RSIC) ceramic belongs to a new type of inorganic non-metallic material. It is made from high purity green sic powder,formed by slip casting way, fired under 2500C.With many excellent properties, it is getting more popular with technical ceramics,high-tech equipment manufacturing,high temperature materials and other fields.

The features of Recrystallized Silicon Carbide (RSIC)

Max temperature is 1700 ℃

High thermal conductity,energy saving

Big hardness,wear &corrossion resistance

Better anti-oxidation performance,longer life

Light weight, while higher loading capacity

Recrystallized Silicon Carbide (RSIC) Kiln Furniture

Our company’s recrystallized silicon carbide Kiln Furniture products mainly includes recrystallized silicon carbide (RSIC)beam, recrystallized silicon carbide(RSIC) plate, recrystallized silicon carbide (RSIC)burner nozzle, recrystallized silicon carbide(RSIC) tubes,recrystallized silicon carbide crucible(RSIC),thermcouple sheath,customized parts etc.Further process is also available, like,alumina coating,grinding,grooving,drilling etc.

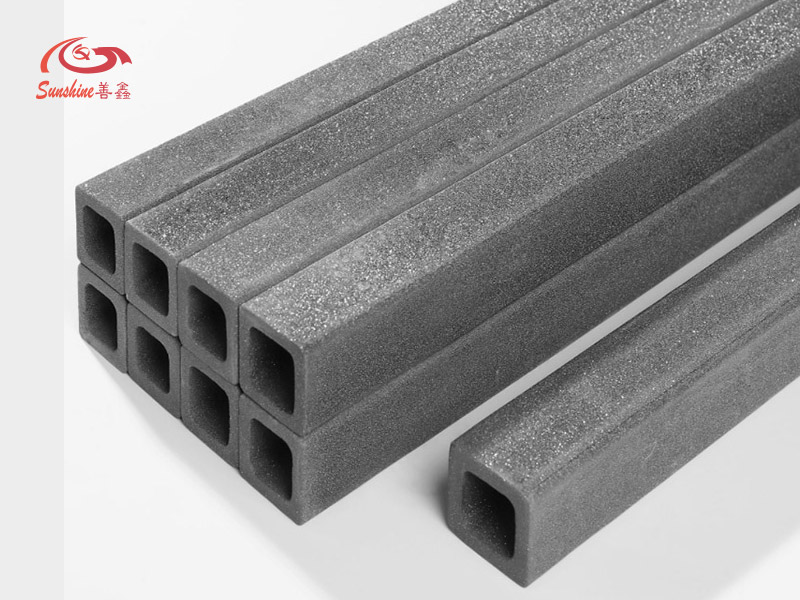

Recrystallized silicon carbide RSIC beam

Recrystallized silicon carbide RSIC beam as kiln furniture widely used for loading structure systems of high temperature industrial kilns or furnace parts.RSiC beams are higher in strength & no deformation even at working temperature of 1650℃-1700℃. And excellent thermal conductivity lead to energy saving with less weight of kiln car with longer serving life.

Application of Recrystallized silicon carbide Rsic Beam

1,Al2O3 & Zr2O3 Ceramics

2,Foam and honeycomb ceramics

3,ITO target & Magnetic Materials

4, High Temperature Fiber Products and Electrical Porcelains

5,Cordierite Mullite Ceramics

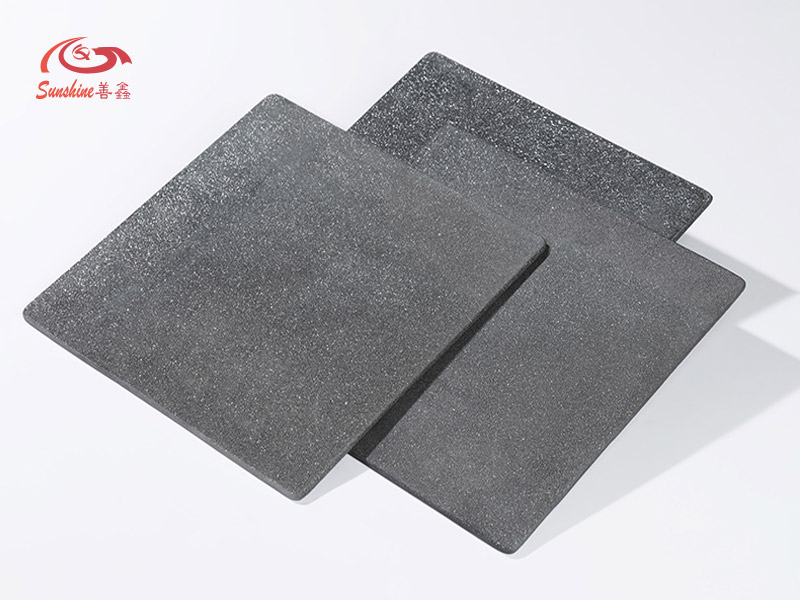

Recrystallized silicon carbide RSIC plate

Recrystallized Silicon Carbide Ceramics Plate is a board made from high-purity and highly active SiC raw materials through high-temperature recrystallization technology.Recrystallized silicon carbide RSIC plate has higher loading capacity with smaller thickness, higher thermal conductivity, also no deformation and good oxidation resistance under 1700 ℃.Mainly as kiln shelves in the following industry:

Kiln Furniture: Used as setters, shelves, or beams in ceramic/refractory sintering furnaces (e.g., alumina, zirconia).In high-temperature furnaces, it can be used as lining materials to provide a stable operating environment.

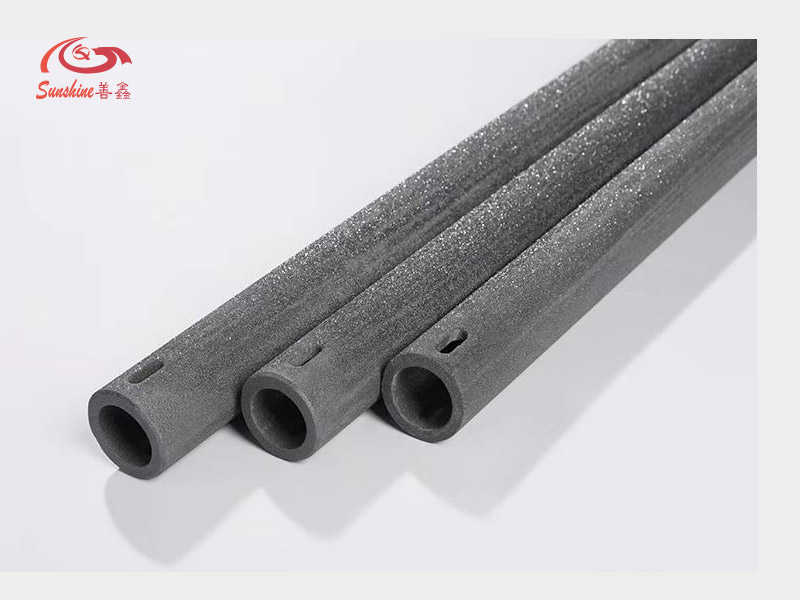

Recrystallized Silicon Carbide RSIC Roller

Recrystallized Silicon Carbide RSIC Roller including “tubes”“Furnace pipe”and“thermal couple protection tube”.Recrystallized silicon carbide roller is made by sintering high-purity and highly active SiC raw materials in a vacuum induction furnace at high temperature of 2420 ℃.

With higher bending strength and excellent wear resistance, high temperature resistance, no deformation under long term working temperature 1700 ℃.

Application of Recrystallized Silicon Carbide RSIC Roller

1.Ceramic industry:Recrystallized Silicon Carbide RSIC Roller is used in ceramic roller kilns can withstand high temperatures, heavy loads, and corrosive gases.

2.Glass industry: recrystallized silicon carbide Rsic roller can be used as glass melting furnace roller,it can withstand high temperature corrosion and wear with long service life.

3.Iron and steel smelting industry: recrystallized silicon carbide roller rod can be used to manufacture refractory lining, steel making roller rod, continuous casting roller rod, etc. They have high temperature oxidation resistance, wear resistance and impact resistance, which can effectively extend the service life of equipment and improve production efficiency.

Recrystallized silicon carbide RSIC burner nozzle is an ideal kiln parts for shuttle kiln,tunnel kiln & roller kiln.Very popu lar with kiln manufacturers, can be instead of SIC burners. Recrystallized silicon carbide RSIC burner nozzle has excellent oxidization resistance and longer using life under 1700 ℃.Non-crack on firing products under super high temperature.

Widely applied in Natural gas, liquefied gas, coal gas, diesel oil industrial kiln which ceramics, chemical, glass,metallurgy…working temperature 1680℃, even 1700℃.To fit:

Tunnel kiln

Shuttle klin

Roller hearth kiln

Recrystalized silicon carbide (RSIC) saggers and crucibles

Recrystalized silicon carbide (RSIC) saggers and crucibles have excellent proterties of high temperature, high strength,oxidization resistance and corrosion resistance,instead of Alumina or Quartz material, as ideal kiln furniture and machine parts,by slip-casting way,can produce special shaped parts according to drawing, want higher precision ceramic, we can do grinding, linear-cutting, threading, grooving and CNC process,widely used for power sintering,scientific testing and advanced machine spares.