อิลิเมนต์ทำจากซิลิคอนคาร์บอนคืออะไร?

Silicon carbide heating elements, also known as sic heating elements or silicon carbide rods, are rod-shaped non-metal high-temperature heating elements made of high-quality green silicon carbide as the main raw material, processed, returned, high-temperature silicified and recrystallized.

ส่วนประกอบฮีติ้งอิลิเมนต์ซิลิคอนคาร์ไบด์เป็นส่วนประกอบฮีติ้งอิลิเมนต์ที่น่าเชื่อถือมาตลอด มีข้อดีคือมีความต้านทานความร้อนที่ปลายขาไม่สูง อายุการใช้งานยาวนาน และประหยัดพลังงาน ส่วนประกอบฮีติ้งอิลิเมนต์ซิลิคอนคาร์ไบด์สามารถใช้ได้ในการกําหนดรูปร่างพื้นฐานแปดแบบที่ช่วยยืดอายุการใช้งานของฮีตเตอร์โดยเฉพาะในสภาพแวดล้อมที่มีการกัดกร่อน

Commonly used types are:

- sg silicon carbide heating element

- ed silicon carbide heating elements

- w silicon carbide heating elements

- sgr silicon carbide heating elements

- u silicon carbide heating elements

- ld silicon carbide heating elements

คุณสมบัติทางกายภาพ

คุณสมบัติทางกายภาพขององค์ประกอบการทําความร้อนซิลิคอนคาร์ไบด์

| ความหนาแน่นที่มีความจำเพาะ |

2.6~2.8g/cm³ |

ความแข็งงอ |

>300kg |

| ความแข็ง |

>9MOH’S |

ความแข็งแรงในการดึง |

>150Kg.cm3 |

| อัตราความพรุน |

<30% |

การแผ่รังสี |

0.85 |

| ความนำความร้อน |

14-19W/m·℃

(1000℃) |

ความจำเพาะความร้อน |

1.0 กิจิเจาะต่อกิโลกรัม·องศาเซลเซียส

(25~1300℃) |

| ความแข็งแรงที่จะฉีกขาด |

50Mpa(25°C) |

สัมประสิทธิ์การขยายตัวด้วยความร้อน |

1.0 กิจิเจาะต่อกิโลกรัม·องศาเซลเซียส

(25~1300℃) |

ลักษณะไฟฟ้า

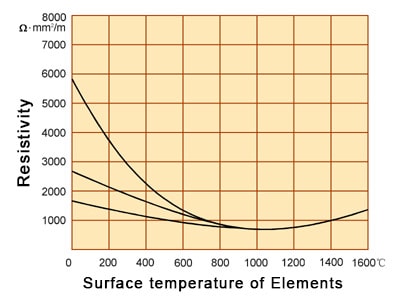

Sic heating elements has rather large specific resistance. When it is heated in air and the surface temperature of the hot zone reaches 1050℃, its resistance rate is 600-1400 mm2/m. Its resistance value changes as the temperature rises.

From room-temperature to 800℃ is negative value, over 800℃ is positive value nature curve.

All silicon carbide elements gradually increase in resistance during their life in operation and the rate at which this occurs is affected by the following factors:

- ชนิดฮีตเตอร์

- Element Specific Loading (W/cm2)

- อุณหภูมิการทํางาน

- บรรยากาศกระบวนการ

- Mode of operation - continuous or intermittent

- การปฏิบัติงาน

คุณสมบัติทางไฟฟ้าขององค์ประกอบการทําความร้อนซิลิคอนคาร์ไบด์

การโหลดบนผิวของฮีตเตอร์

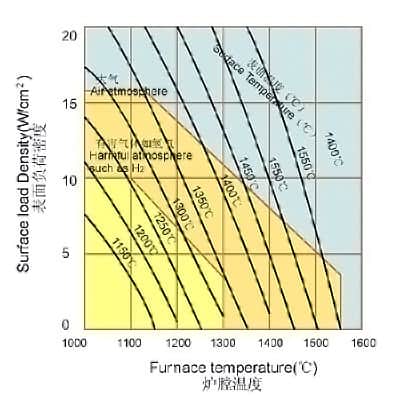

The key factor to the optimum service life of the element is to select the surface load of the element correctly according to the furnace construction, atmosphere and temperature below.

The curves show maximum specific element loading for different element types operated in air. These values may be used as a guide, but for maximum element life a lower loading should be used wherever possible.

การโหลดที่ต่ํากว่าอาจจําเป็นด้วยที่ซึ่งส่วนทําความร้อนจะถูกใช้งานในบรรยากาศรีดิวซิ่งหรือบรรยากาศกระบวนการอื่นๆ เพื่อรักษาอุณหภูมิของส่วนทําความร้อนให้อยู่ในขีดจํากัด ดูตารางด้านล่าง

การเกาะติดของอนุภาคบนผิวหน้าองค์ประกอบการทําความร้อนซิลิคอนคาร์ไบด์

| อุณหภูมิ(℃) |

Linear expansion coefficient

(10-6m/℃) |

Heat conductivity

(Kcal/M ชั่วโมง ℃) |

ความจำเพาะความร้อน

(cal.g℃) |

| 0 |

/ |

/ |

0.148 |

| 300 |

3.8 |

/ |

/ |

| 400 |

/ |

/ |

0.255 |

| 600 |

4.3 |

14-18 |

/ |

| 800 |

/ |

/ |

0.294 |

| 900 |

4.5 |

/ |

/ |

| 1100 |

/ |

12-16 |

/ |

| 1200 |

4.8 |

/ |

0.325 |

| 1300 |

/ |

10-14 |

/ |

| 1500 |

5.2 |

/ |

/ |

常用的silicon carbide heating elements类型有:

<

ดังนั้น ท่อนไฟฟ้าซิลิคอนคาร์บอนมีการใช้งานอย่างแพร่หลายในหลายธุรกิจ เช่น วัสดุแม่เหล็กแม่เหล็ก โลหะผง โครมมิค กละสี โลหะและเครื่องจักร ซึ่งมีเตาไฟฟ้าอุณหภูมิสูงต่าง ๆ และเครื่องมือทำความร้อนไฟฟ้าอื่น ๆ

คาร์ไบด์ซิลิคอนโรดในเตา

คาร์ไบด์ซิลิคอนโรดในเตา

องค์ประกอบการทําความร้อน Sic เทียบกับองค์ประกอบการทําความร้อนโลหะไฟฟ้า

Compared with metal electric heating elements, Sic heating elements have the characteristics of high operating temperature, oxidation resistance, corrosion resistance, long life, low deformation, and convenient installation and maintenance.

คําถามที่พบบ่อย:

วิธีเลือกอุปกรณ์จ่ายไฟ?

Power supply equipment should be selected with a large regulating range voltage and it is a stable and continuous voltage regulating equipment, such as magnetic voltage regulator, silicon controlled DC voltage regulator, etc. If you choose a stage voltage regulator transformer, you should also choose a transformer with a small voltage difference .

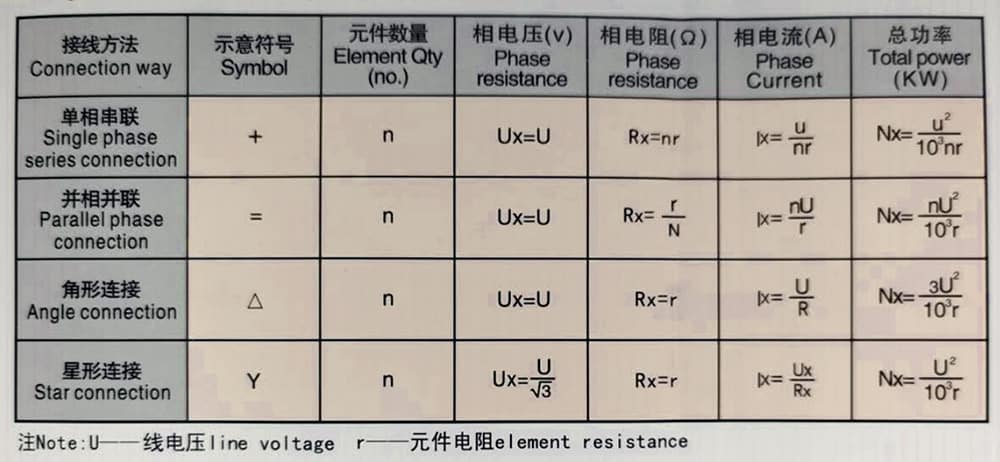

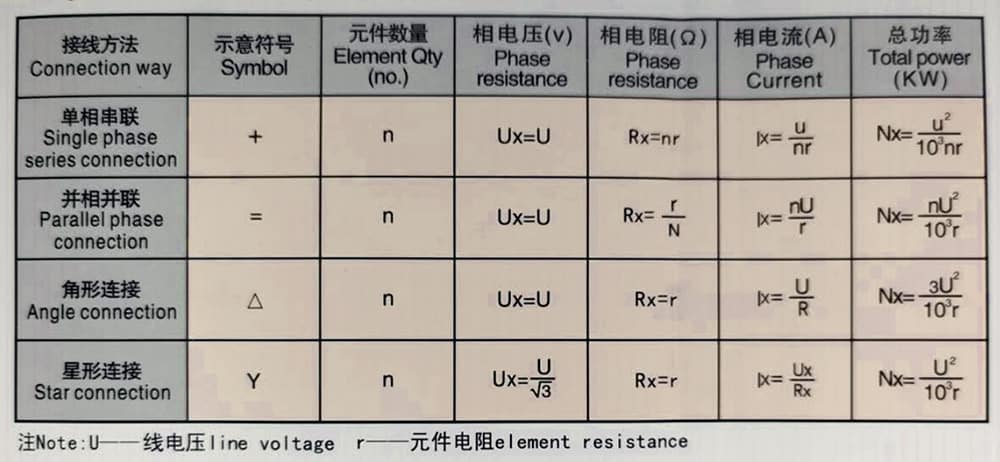

การเชื่อมต่อของหลอดซิลิคอนคาร์ไบด์เป็นอย่างไร?

วิธีการเชื่อมต่อขององค์ประกอบของท่อคาร์บอนซิลิคอนสามารถเชื่อมต่อเป็นชุดหรือขนาดเท่ากันและเชื่อมต่อแบบขนาดเท่ากันเป็นที่ดี ขณะใช้งานแบบชุด จำนวนของสาขาในลำดับไม่ควรเกิน 3 สาขา

วิธีการเชื่อมต่อทั่วไปและสูตรคำนวณของมันระบุในตารางข้อมูลดังต่อไปนี้

การคํานวณกําลังไฟฟ้าของวิธีการเดินสายทั่วไปบางวิธี

Installation and Operation of Element

การติดตั้งแนวนอนและแนวตั้งเป็นวิธีการติดตั้งทั่วไป ต้องให้ความระมัดระวังเป็นพิเศษในการยึดติดเพื่อให้แน่ใจว่าฮีตเตอร์ไม่ถูกดึงเข้าหากัน ควรมีช่องว่างเพียงพอให้เตาและฮีตเตอร์ขยายตัวและหดตัวได้อิสระ

When mounting elements vertically, they must be supported on the lower end by electrically insulated supports, or from above using support pins on an isolating plate of sufficient strength to support the weight of the elements.The elements ends should extend beyond the furnace cold face by a minimum distance of 76.2mm to 101.6mm.

- 1) In order to keep furnace temperature and the load-bearing uniform of each element, before installation, resistance distribution must be carried out. The resistance value deviation of each group should be below 10%.

- 2) As the element is very brittle, be careful while install and maintain to avoid any damage.

- 3) When start to operate the furnace, raise voltage slowly and gradually, never give full load at one time, or the heating element will be damaged by over current impulse.

- 4) ในการใช้งานฮีตเตอร์ ควรเตรียมแปลงสัญญาณ, หม้อแปลงซิลิคอนควบคุม, โวลต์มิเตอร์, แอมมิเตอร์ และอุปกรณ์วัดอุณหภูมิอัตโนมัติ ในระหว่างการทํางานควรเพิ่มแรงดันไฟฟ้าเพื่อรักษาอุณหภูมิเตาตามปกติ เนื่องจากค่าความต้านทานจะเพิ่มขึ้นเรื่อยๆจากการออกซิไดซ์ของฮีตเตอร์ เมื่อแรงดันถึงขีดจํากัดสูงสุด ควรหยุดเตา เปลี่ยนวิธีเชื่อมต่อสายไฟ แล้วทํางานต่อ

- 5) ในระหว่างการทํางานของเตาอบเป็นเวลานาน หากฮีตเตอร์ตัวใดตัวหนึ่งเสียหายจากสาเหตุใดก็ตามและต้องเปลี่ยน ควรเปลี่ยนด้วยฮีตเตอร์ที่มีค่าความต้านทานตรงกับของเดิม ห้ามใช้ฮีตเตอร์ใหม่สุ่มเสี่ยง หากฮีตเตอร์เสียหายมากหรือค่าความต้านทานเพิ่มขึ้นจนไม่สามารถทําให้เตาร้อนได้ ควรเปลี่ยนฮีตเตอร์ทั้งหมด ทดสอบและจดบันทึกค่าความต้านทานของฮีตเตอร์เก่าที่ถูกเปลี่ยน (ด้วยโวลต์มิเตอร์และแอมมิเตอร์) แล้วกระจายไปในบริเวณอุณหภูมิต่ํา

- 6) ก่อนใช้เตาอบใหม่ของเตาอบที่ไม่ได้ใช้งานมาเป็นเวลานาน ต้องอบแห้ง ขณะอบแห้งควรใช้ส่วนทําความร้อนเก่าหรือแหล่งความร้อนอื่น

- 7) เมื่อเผาวัสดุหรืออุปกรณ์ หากมีน้ําเป็นไอออกมา เตาควรมีรูเพื่อให้ไอน้ําหรือก๊าซเสียอื่นๆ ระบายออก เพื่อปกป้องอายุการใช้งานของฮีตเตอร์

วิธียืดอายุการใช้งานของฮีตเตอร์?

ค่าความต้านทานของอิลิเมนต์ทำความร้อนจะเพิ่มขึ้นและแก่ไปพร้อมกับการให้บริการต่อไป ขณะที่ค่าความต้านทานของอิลิเมนต์เพิ่มขึ้นถึง 3 ครั้งของค่าความต้านทานเริ่มต้น จะถือว่าเป็นจุดสิ้นสุดของอายุการให้บริการ มีปัจจัยหลายประการที่มีผลต่อการสูญเสียอายุของอิลิเมนต์ทำความร้อน:

- อุณหภูมิการทํางาน

- การโหลดไฟฟ้า (โดยทั่วไปแสดงเป็นวัตต์ต่อตารางนิ้วหรือวัตต์ต่อตารางเซนติเมตรของพื้นผิวการแผ่รังสีของส่วนทําความร้อน)

- บรรยากาศ

- ประเภทการดำเนินการ (ต่อเนื่องหรือเป็นแบบสับสน)

- เทคนิคการปฏิบัติงานและการบํารุงรักษา

แบบจําลองตัดขวางเตาห้องปฏิบัติการอุณหภูมิสูง

When used in 1450 ℃ clean oxidation atmosphere, the heating element can obtain a relatively long service life. In order to achieve the best service life, the surface load as low as possible should be considered when designing the furnace, and 3-8w/cm² is recommended