เกรดของชิ้นส่วนทำความร้อน Mosi2

1700 Grade

Maximum Element Temperature – 1700°C (3090°F)

การประยุกต์ใช้ทั่วไป

เตาอุตสาหกรรมส่วนใหญ่สําหรับการรักษาความร้อน การตีขึ้นรูป การไส การหลอมและกลั่นแก้ว และสําหรับใช้ในท่อแผ่รังสี

- ผลิตภัณฑ์มีความสามารถในการต้านการออกซิเดชันและการซ่อมแซมโดยอัตโนมัติ เหมาะสำหรับการใช้งานต่อเนื่องในสภาพอากาศที่มีการออกซิเดชันใด ๆ

- ผลิตภัณฑ์ถูกสร้างรูปร่างในกระบวนการเป็นร้อน ซึ่งช่วยรักษาความยืดหยุ่นและความหยดหยุ่นของวัสดุฐานในอุณหภูมิสูง รูปร่างทางเรขาคณิต มาตรฐาน และขนาดเป็นแบบมาตรฐาน สามารถผลิตรูปร่างพิเศษและขนาดพิเศษใด ๆ เพื่อตอบสนองความต้องการของลูกค้า

- เนื่องจากเทคโนโลยีพิเศษ จุดต่อเชื่อมทําได้เร็วและทนต่อการกระแทก ซึ่งลดความเสี่ยงของความเสียหายที่จุดต่อเชื่อมจากกระแสไฟฟ้า รวมถึงการขนส่งและการติดตั้งได้อย่างมาก

- นําเทคโนโลยีพิเศษมาใช้ ส่วนทําความร้อนมาพร้อมกับชั้นป้องกันที่กระชับ มีประสิทธิภาพดีในเตาอบไฟฟ้าบรรยากาศไม่ออกซิไดซ์

- อิลิเมนต์ใหม่และเก่าสามารถทํางานในกลุ่มควบคุมเดียวกันได้

- พลังงานสูงทำให้เป็นไปได้ในการเพิ่มอุณหภูมิเตาอย่างรวดเร็ว

1800 Grade

Maximum Element Temperature – 1800°C (3270°F)

การประยุกต์ใช้ทั่วไป

เตาอบห้องปฏิบัติการ อุปกรณ์ทดสอบ และเตาผลิตภัณฑ์ไสสูงอุณหภูมิ

- ผลิตภัณฑ์มีความสามารถในการต้านการออกซิเดชันและการซ่อมแซมโดยอัตโนมัติ เหมาะสำหรับการใช้งานต่อเนื่องในสภาพอากาศที่มีการออกซิเดชันใด ๆ

- ผลิตภัณฑ์ถูกสร้างรูปร่างในกระบวนการเป็นร้อน ซึ่งช่วยรักษาความยืดหยุ่นและความหยดหยุ่นของวัสดุฐานในอุณหภูมิสูง รูปร่างทางเรขาคณิต มาตรฐาน และขนาดเป็นแบบมาตรฐาน สามารถผลิตรูปร่างพิเศษและขนาดพิเศษใด ๆ เพื่อตอบสนองความต้องการของลูกค้า

- เนื่องจากเทคโนโลยีพิเศษ จุดต่อเชื่อมทําได้เร็วและทนต่อการกระแทก ซึ่งลดความเสี่ยงของความเสียหายที่จุดต่อเชื่อมจากกระแสไฟฟ้า รวมถึงการขนส่งและการติดตั้งได้อย่างมาก

- นําเทคโนโลยีพิเศษมาใช้ ส่วนทําความร้อนมาพร้อมกับชั้นป้องกันที่กระชับ มีประสิทธิภาพดีในเตาอบไฟฟ้าบรรยากาศไม่ออกซิไดซ์

- อิลิเมนต์ใหม่และเก่าสามารถทํางานในกลุ่มควบคุมเดียวกันได้

- พลังงานสูงทำให้เป็นไปได้ในการเพิ่มอุณหภูมิเตาอย่างรวดเร็ว

อุณหภูมิระดับ 1850

The unique properties

- High temperature MoSi2 heating element for various electric furnaces.

- Maximum Element Temperature – 1850°C (3360°F), safety running for operating temp. 1750 ℃

- อายุการใช้งานยาวและง่ายต่อการเปลี่ยน ช่วยให้การใช้งานเตาสูงและต้นทุนการบํารุงรักษาต่ํา

- New and old elements can be use together and in series.

- สามารถกระจายพลังงานโหลดสูงได้

- สามารถใช้งานต่อเนื่องหรือสลับกันได้

- ให้อัตราการเพิ่มอุณหภูมิเตาที่รวดเร็ว

การประยุกต์ใช้ทั่วไป

Laboratory furnaces, testing equipment, and high temperature sintering production furnaces up to 1800°C furnace temperature.

อุณหภูมิระดับ 1900

- Max. working temperature 1850 ℃, safety running for operating temp. 1750 ℃

- Elements may be used at surface temperature up to 190oºC, at control furnace temperatures up to 1750ºC in oxidizing atmospheres. Lower temperatures are recommended in reducing atmospheres.

- High density of SUNSHINE product increases its electrical conductivity. The characters of faster warming and power consumption low, which reduce production cost.

- คุณภาพภายนอกดี มีความยืดหยุ่นสูง ความแข็งแรงทางกลสูง

- การใช้ทั่วไป - องค์ประกอบการทําความร้อน MoSi2 อุณหภูมิสูงสําหรับเตาอบไฟฟ้าประเภทต่าง ๆ

Super Pure MoSi2 Heating Element

(Used for Dental industrial Furnace)

Mosi2 as raw material, the purity is very high.In the manufacturing of mosi2 heating element ,we adopt hi-tech method, it make the element’s surface generate very dense silica membranes,and offer a protection of having thin quartz firm outside when sintering at 1600 Celsius.

When zirconia ceramics dentures is sintering,super pure mosi2 heating element will not bring yellow-dish color on the zirconia unit inside the chamber.

- The main material (MoSi2)has a higher purity.

- High purity MoSi2 heating element, for various electric furnaces , especially dedicate for high purity furnace.

- Max. working temperature 1850 ℃ .

- The diameter including hot zone and cold zone are more accurate, avoiding uneven heating and prevent arsing impurities.

- more compact protective film, higher adhesive strength with substrate.

- Good high-temperature strength,not easy to deformation in use.

การใช้งาน

ฮีตเตอร์ Mosi2 สามารถใช้อย่างแพร่หลายในการเตรียมและบําบัดความร้อนผลิตภัณฑ์เซรามิก สนามแม่เหล็ก แก้ว โลหะวิทยา เซรามิกทนไฟ เป็นต้น ฮีตเตอร์ Mosi2 เป็นส่วนสําคัญในกระบวนการเตรียมความร้อนเซรามิกสมรรถนะสูง ผลึกเทียมชั้นสูง เซราเมตซับพื้นผิวซับซ้อน ใยแก้ว สายเคเบิลเส้นใยแก้ว และเหล็กผสมชั้นสูง และเป็นผลิตภัณฑ์ที่เป็นมิตรต่อสิ่งแวดล้อมที่ดีที่สุดในยุคศตวรรษที่ 21

- เหมาะสำหรับเตาอุณหภูมิสูงชนิดที่ต้องการให้ความร้อนและเย็นบ่อยครั้งแบบสลับกัน

- เหมาะสำหรับเตาทันตกรรมโดยไม่มีการเปลี่ยนสี, การประยุกต์ใช้ในกระบวนการเผาผลาญด้วยอุณหภูมิที่เปลี่ยนแปลงอย่างรวดเร็ว

- เหมาะสำหรับผลิตภัณฑ์ที่ผ่านกระบวนการเผาผลาญโดยเครื่องที่มีเขตการรอบรอบอุณหภูมิที่เข้มงวด

MoSi2 heating elements are available in the following common types

ลักษณะทางกายภาพ

- Volume Density: 5g/cm3

- Bending Strength: 15-25kg/cm3

- Vickers Hardness(HV): 570kg/mm2

- ความพรุน: 4%

- การดูดซับน้ำ: 2%

- อัตราการยืดขยายเมื่อทําความร้อน: 4%

ลักษณะทางเคมี

ต้านทานออกซิเจนในสภาวะอุณหภูมิสูง: ในบรรยากาศออกซิไดซ์ ชั้นเคลือบควอตซ์ (SiO2) ที่หนาแน่นจะถูกสร้างขึ้นบนผิวหน้าขององค์ประกอบจากการเผาไหม้ที่อุณหภูมิสูง ซึ่งช่วยป้องกันไม่ให้ Mosi2 เกิดการออกซิไดซ์อย่างต่อเนื่อง

When the element temperature is higher than 1700C,the sio2 protective film will be fused because its fusing point is 1710C and the sio2 is fused into molten dropa owing to the action of its surface extension,which cause losing its protective ability .In the oxidizing atmosphere, when the element is continuously used, the protective film forms again.

The MoSi2 heating element must not be used in the temperature between 400C and 700C for a long time, otherwise the element will be cremated under the strong oxidizing function in the low temperature.

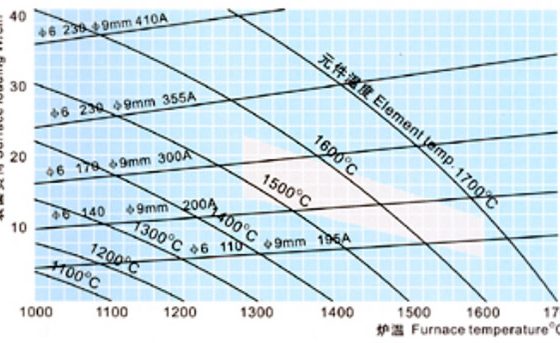

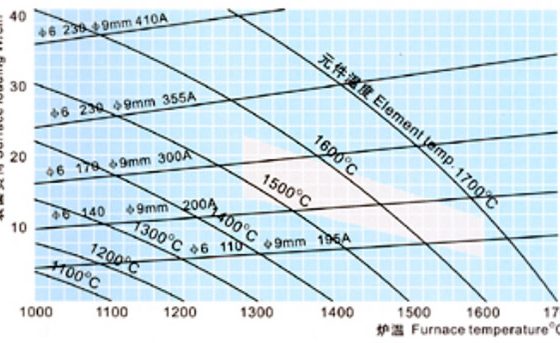

ภาระผิว

According to the structure, the temperature and atmosphere in the correct choice of components surface load is the key element to the highest life, based on the thermal radiation components uncrossed circumstance temperature, temperature and surface load components, the shaded part for common surface load -- the temperature range.

อัตราการโหลดผิว

ส่วนประกอบฮีติ้งอิลิเมนต์ MoSi2 พื้นที่รองรับน้ําหนัก

| อุณหภูมิเตา (°C) |

1400 |

1500 |

1600 |

1650 |

1700 |

| โหลดพื้นผิวของโซนร้อน (วัตต์ต่อตารางเซนติเมตร) |

<18 |

<15 |

<12 |

<10 |

<8 |

แอมป์สูงสุด

องค์ประกอบ Moly-D เป็นองค์ประกอบที่มีแรงดันไฟฟ้าต่ำและกระแสไฟฟ้าสูง ด้านล่างนี้เป็นกระแสสูงสุดที่แนะนำสำหรับแต่ละเส้นผ่านศูนย์ร้อนมาตรฐาน โซนร้อนสามารถรับกำลังได้มากกว่านี้ แต่ปลายที่เย็นจะมีความร้อนมากเกินไปและทำให้รูดและหนีบล้มลง

กระแสไฟฟ้าสูงสุดที่แนะนํา

| เส้นผ่านศูนย์กลางโซนร้อน (มม.) |

3 |

4 |

6 |

9 |

12 |

| กระแสแอมป์ |

75 |

115 |

200 |

365 |

560 |

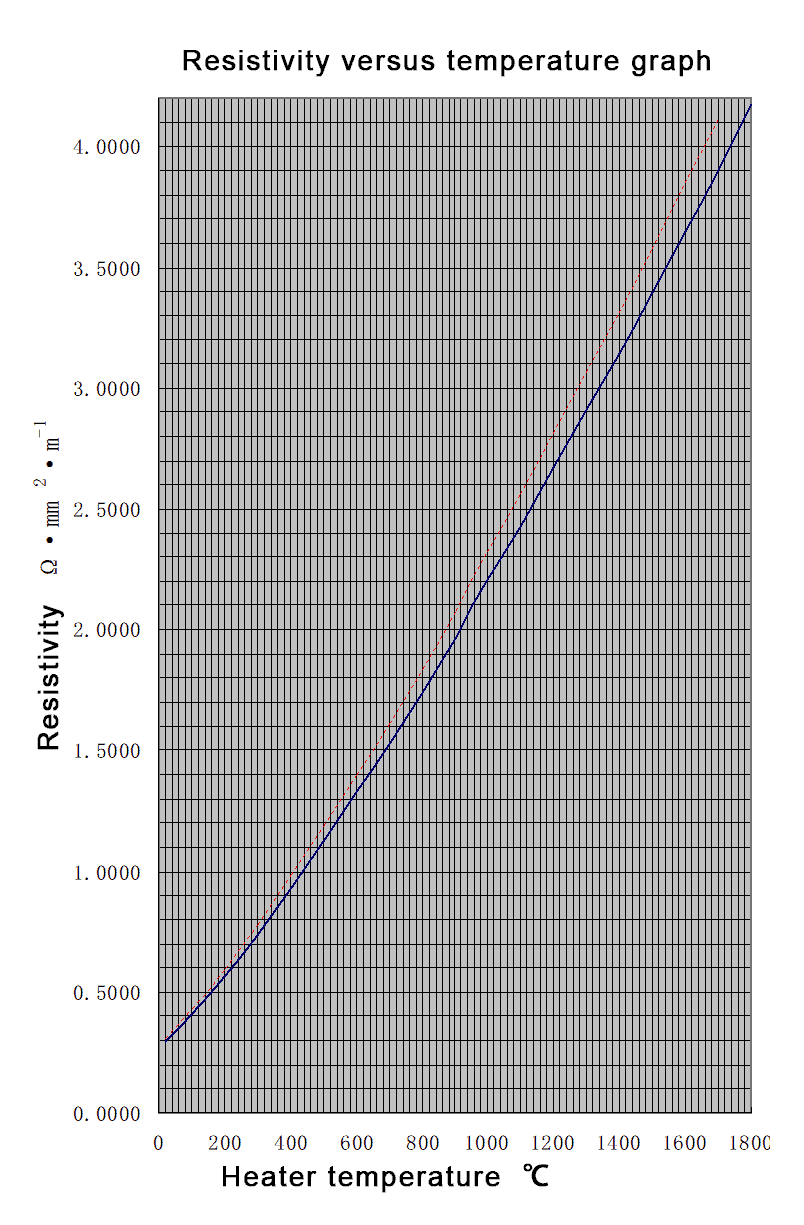

คุณสมบัติในการต้านทาน

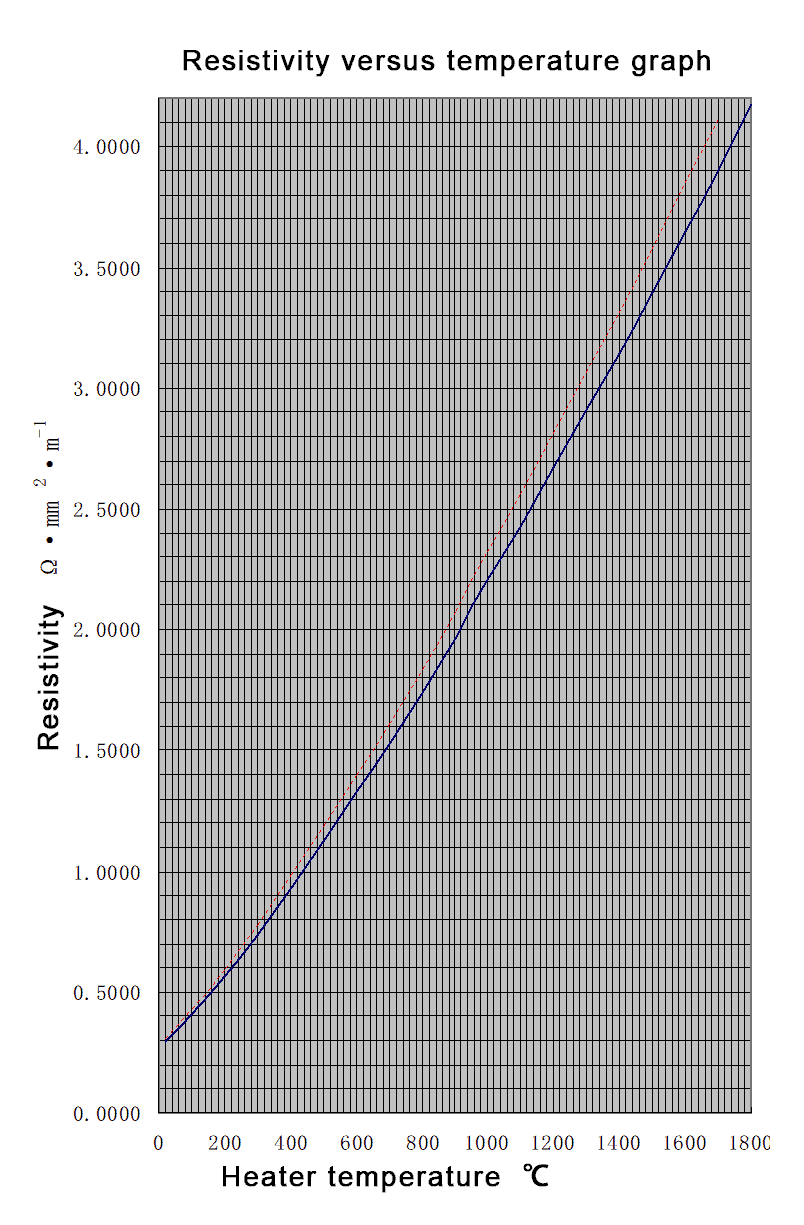

The resistivity of element rapidly rises along with the temperature rises , under normal operating condition,generally the element resistance doesn't change with the application time changing.So the old and new elements can be used together.

คุณสมบัติในการต้านทาน

ชิ้นส่วนที่ใช้ในการทำความร้อน Mosi2 เป็นที่ต้านทานที่แปลงพลังงานไฟฟ้าเป็นพลังงานความร้อนตามกฎของ Joules Law W=I2R. W = พลังงานในวัตต์, I = กระแสไฟฟ้าในแอมป์, R = ความต้านทานในโอห์ม

Molybdenum disilicide increases in resistance by a actor of approximately 10 between 20ºC and 1800ºC.Therefore the hot zone temperature must be known before the resistance of the hot zone can be determined.

The mosi2 element is a high temperature element that performs well and gives long service life at its rated temperature of 1700ºC or 1800ºC. Therefore, we recommend designing to element temperatures of 1675ºC for the grade 1700 Grade and 1775ºC for the grade 1800.

The resistance values for 1mm of length for standard element diameters at 1675ºC and 1775ºC are shown on the following Table.

| ฮอต |

ความต้านทานเป็นโอห์มต่อมิลลิเมตรของความยาว ที่อุณหภูมิ 1675°C และ 1775°C |

| ขนาดเส้นผ่านศูนย์กลางหน้าตัด |

1675℃ |

1775℃ |

| 3 |

0.00493 |

0.000523 |

| 4 |

0.000277 |

0.000294 |

| 6 |

0.000123 |

0.000131 |

| 9 |

0.000054 |

0.000058 |

| 12 |

0.00003 |

0.000032 |

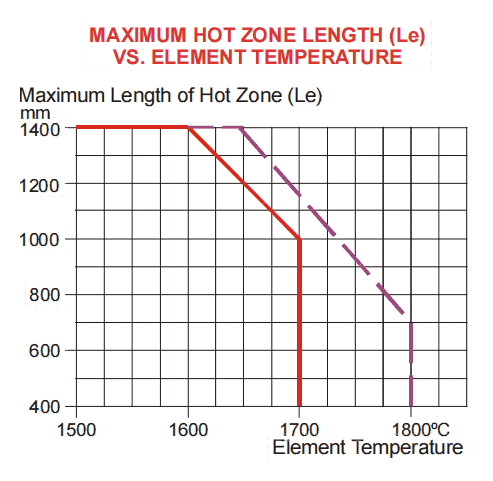

How to design the length of the hot zone

โมลิบดีนไดซิไลได้กลายร่างที่อุณหภูมิมากกว่า 1200ºC ดังนั้นจะยืดหรือยืดเมื่อเห suspend แนวตั้ง อุปกรณ์ทำความร้อนสามารถทำลายได้หากมีการติดต่อกับพื้นของเตาเมื่ออุณหภูมิยังคงสูงและที่เปิดใช้งานอยู่

เพื่อให้เกิดการเพิ่มความยาวและรักษาระยะห่างที่ปลอดภัยจากพื้น, โซนร้อน (Le) ต้องสั้นกว่าความสูงของห้องที่ทำความร้อน

ในการออกแบบความยาวของโซนร้อนจำเป็นต้องผ่านขั้นตอนสองขั้นตอน:

ขั้นตอนที่ 1:

ที่ตําแหน่งในเตาที่องค์ประกอบถูกแขวนอยู่ วัดความสูง (H) เป็นมิลลิเมตร

ขั้นตอนที่ 2:

The taper portion of the cold end (Lu) extends into he hot chamber. This cold end taper length varies with the diameter of the element. See Table D to obtain the taper length (g) inside the hot chamber.

ในการออกแบบความยาวของโซนร้อน (Le) ใช้สูตรหนึ่งในสูตรต่อไปนี้:

สําหรับ H น้อยกว่า 200 มม. Le=H-10-g

สําหรับ H มากกว่า 200 มม. Le=0.95H-g

H = ความสูงของเตาเป็นมิลลิเมตร

g = ความยาวส่วนลาดจากตาราง D

10 = minimum recommended vertical distance beneath the element in mm.

0.95 = shortening of the Le to allow for the element to stretch and be a safe distance above the floor.

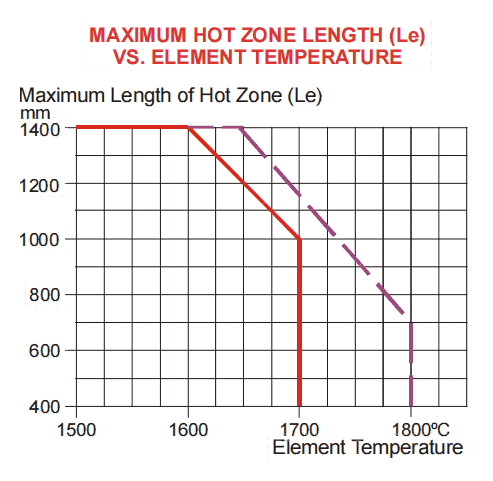

ข้อจำกัดความยาวสูงสุดในส่วนร้อน:

3/6 และ 4/9 คือสัดส่วนแม็กซิมัม Le สูงสุด = 400 มม.

6/12, 9/18 และ 12/24 Le สูงสุด = 1400 มม.

The 6/12, 9/18 and 12/24 maximum lengths are reduced based on element temperatures over 1600ºC

การออกแบบความยาวโซนร้อนของ mos2

How TO calculate the power on a U-SHAPES mosi2 heating element ?

To compute the power in watts on the mosi2 heating element the length of the hot zone, the surface area of the hot zone, and the watt loading in watts per cm2 must be determined.

ความยาวที่ทำความร้อนขององค์ประกอบรูปร่าง "U" ประกอบด้วยขา 2 ขาและการงอ 180º ใช้สูตรด้านล่างเพื่อคำนวณความยาวทั้งหมด

ขั้นตอนที่ 1

เพื่อให้ได้ความยาวรวมของโซนร้อนทั้งหมดในมิลลิเมตร ใช้สมการ: โซนร้อนรวม (LH) = 2(Le) บวก (z) จำนวนจากตารางต่อไปนี้คอลัมน์ที่ 3

LH=2(Le)+z

ขั้นตอนที่ 2

เส้นผ่านศูนย์กลางโซนร้อน

mm |

ตรงกลาง

mm

a |

ความยาวที่เพิ่มให้ Le

mm

z |

Surface Area (mm2) for 1 mm of length

c |

| 3 |

20 |

8.40 |

9.42 |

| 3 |

25 |

11.25 |

9.42 |

| 4 |

20 |

7.40 |

12.56 |

| 4 |

25 |

10.25 |

12.56 |

| 6 |

40 |

16.80 |

18.84 |

| 6 |

50 |

22.50 |

18.84 |

| 6 |

60 |

28.20 |

18.84 |

| 9 |

50 |

19.50 |

28.26 |

| 9 |

60 |

25.20 |

28.26 |

| 12 |

60 |

22.20 |

37.68 |

To obtain the surface area (SA) of this hot zone in square cm, select from Table C, column 4, the surface area (c) of 1 mm length for the element diameter 3, 4, 6,9, 12, or 24 mm. Multiply this by the total from step 1 (LH).

This number will be the total surface area of the hot zone in square mm. To convert the units from square mm to square centimeters (cm), divide by 100.

สัญญาณในอารมณ์ที่แตกต่างกัน

| บรรยากาศ |

1700 |

1800 |

1850 |

1900 |

| อากาศ |

1700 |

1800 |

1830 |

1850 |

| ไนโตรเจน |

1600 |

1700 |

1700 |

1700 |

| Ar Ne อาร์กอน เฮเลียม |

1600 |

1700 |

1700 |

1700 |

| Dry Hydrogen (dew point)-80℃ |

1150 |

1150 |

1150 |

1150 |

| Wet Hydrogen (dew point)-20℃ |

1450 |

1450 |

1450 |

1450 |

| แก๊สภายนอก (เช่น 10% CO)2, 50% คาร์บอนมอนอกไซด์, 15% ไฮโดรเจน2) |

1600 |

1700 |

1700 |

1700 |

| แก๊สภายนอก (เช่น 40% CO)2, 20% คาร์บอนมอนอกไซด์) |

1400 |

1450 |

1450 |

1450 |

| รอยแตกและไหม้บางส่วนจากแอมโมเนีย (8%H2) |

1400 |

1450 |

1450 |

1450 |

The advice for first firing

When the elements are new (first used) they must be brought to an element temperature of 1200ºC or higher quickly in air. If operated at a surface temperature in the 500ºC to 700ºC range for any length of time before the glaze is formed the elements will be destroyed.

หลังจากการเคลือบแก้วเกิดขึ้น ส่วนทําความร้อนอาจทํางานได้ที่อุณหภูมิต่ําตราบใดที่เคลือบแก้วยังคงเหลืออยู่

คำแนะนำในการใช้งานเตา

เพื่อป้องกันการกระชากกระแซงกระแสไฟฟ้าสูงที่อาจเป็นสาเหตุให้เกิดความเสียหายต่ออุปกรณ์ทำความร้อน MoSi2 ของเรา ขั้นตอนการเริ่มต้นที่แนะนำคือดังนี้:

| เตาเล็ก (กำลังไฟ 100 กิโลวัตต์) |

เตาอบใหญ่ (กําลัง 100KW-500KW) |

| Furnace Temperature C |

แรงดัน |

Furnace Temperature C |

แรงดัน |

| 20-150 |

1/3 |

20-300 |

1/3 |

| 150-500 |

2/3 |

300-700 |

2/3 |

| อุณหภูมิการทํางาน 500 |

เต็ม |

700-อุณหภูมิทํางาน |

เต็ม |

| Note: Shifting gear must be done quickly, otherwise high current surges may cause damage. |

Installation and Advice

ติดตั้งแนวตั้ง

Under normal temperature, MoSi2 element is very brittleness, while under high temperature it is plasticity. So, the better way for installation if the U Shape element is to hang it vertically, to the furnace top through the support clamping chuck H.

The aim of such way is to avoid putting the mechanical stress directly to the element heat-generating end, or the element will easily be broken.

ปะเก็นรองรับ

Support clamp are applied to &9/18 and &6/12 two kinds of elements respectively. The support clamp supports the whole weight of the element and the position of the element is also determined by it.

ดังนั้น จะต้องติดตั้งโดยรอบอย่างระมัดระวังเพื่อให้แน่ใจว่าท่อนไฟฟ้าติดแนวตั้ง และเพื่อป้องกันไม่ให้ท่อนไฟฟ้าได้รับความร้อนมากไปในบางส่วน ส่วนตัดเป็นเทปที่ด้านล่างของท่อนไฟฟ้าจะต้องใส่เข้าในห้องเตา

wire clip

The wire connection clamp connecting MoSi2 element is made of aluminum woven wire or multilayer aluninum foil. The steel plate outside it only acts as a clamp and isn't used for electric conduction.

For 6/12 element, single rowing wire is used ,and for &9/18element,double-rowing wire is used ,the end of the lead wire should be a little larger than the linear distance between the element and bus.

The brittleness of MoSi2 heating element is relative more under the usual temperature; it also has plasticity under the high temperature. So you had better hang and erect vertically the "U"-shape element. If you need to erect it horizontally, please choose a support of high-temperature insulating materials. The cone-part of the element must extend inside the furnace.

ในตอนแรกที่จับขั้วต่อไฟของ MoSi2 ไม่ควรขันแน่นเกินไป เมื่ออุณหภูมิขององค์ประกอบเพิ่มขึ้น ให้ขันแน่นอีกครั้ง จะช่วยป้องกันไม่ให้องค์ประกอบแตกหักได้ง่าย

(คําแนะนําของเราโปรดเลือกตัวเชื่อมต่อพลังงานที่เป็นพิเศษจากบริษัทของเรา

ฝาเตาควรมีฟังก์ชันการรักษาความร้อนที่ดี โดยทั่วไปแล้ว อุณหภูมิของฝาเตาไม่ควรเกิน 300 องศาเซลเซียส แรงดันควรเป็นต่ำ 0.1 ระหว่างตัวเชื่อมไฟฟ้าและองค์ประกอบ

In order to avoid radiating heat to pass the connector, the distance is not less than 50mm between the low end of connector and the upside of the ceramic brick. The Dia.6 element can't be used of 170A for a long time. The Dia.9 element can't be used of 300A for a long time.