Product details of Sunshine ceramic fiber blanket

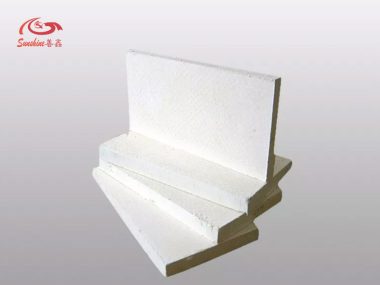

Sunshine ceramic fiber blanket is made of special ceramic fiber through double needle-punching processing. The double needle-punching techniques improve the degree of fiber inter texture, and the performance of delamination resistance as well as tensile strength.The product does not contain any bonding agent and with the characteristics of stable chemical performance, resistance to the erosion of most chemicals.The physical property like refractory and insulation keep same when meet with oil,water or steam.

Sunshine ceramic fiber blanket can be cut into different sizes according to the user needs.They can also be wrapped with aluminum foil on one or both sided to meet the requirements of different industries.

The advantage of Sunshine ceramic fiber blanket

The ceramic fiber blanket is high strength, needled insulating blanket.The combination of long spun fibers and needling operation produce tough, resilient and strong blankets, which resist tearing both before and after heating.It can be folded, compressed and encapsulated to produce module.

The characteristics of Sunshine ceramic fiber blanket

Excellent chemical stability,nonflammable.

Low thermal conductivity and good insulation.

Good tensile strength and springiness.

Excellent performance of soundproofing Good obstructing and resistance to heat-shock.

The applications of Sunshine ceramic fiber blanket

Internal and external lining for industry furnace.

Internal and external insulation for Pipeline.

Insulation for home application, nuclear power and aerospace.

Joint sealing and filing insulation.

Expansion seals/pipe coverings.

The technical index of Sunshine ceramic fiber blanket

| Item | SS1260 STD | SS1260 HP | SS1350 HA | SS1400 LZ | SS1430 HZ | SS1600℃ | |

| Max Service Temp(℃) | 1260 | 1260 | 1350 | 1400 | 1430 | 1600 | |

| Density (kg/m³) | 96/128/140/160 | 96/128 | |||||

| Linear hrinkage(%) (24h,128 KG/M³) | ≤4.01050℃ | ≤4.0 1100℃ | ≤4.0 1200°C | ≤4.0 1250°C | ≤4.0 1350°C | ≤1.0 1500℃ | |

| (Kpa) (128 KG/M³)Tensile Strength | 75 | 75 | 55 | 75 | 75 | 75 | |

| Thermal conductivity rate(W/m.k) | 600℃ | 0.15 | 0.15 | – | – | – | – |

| 800℃ | 0.22 | 0.21 | 0.21 | 0.21 | 0.21 | 0.19 | |

| 1000℃ | 0.31 | 0.30 | 0.31 | 0.31 | 0.31 | 0.28 | |

| Chemical Composition(%) | Al2O3 | ≥42 | ≥45 | 52~55 | ≥37 | ≥37 | ≥70 |

| Al2O3+SiO₂ | ≥98 | ≥98 | ≥98 | ≥92 | ≥83 | ≥99 | |

| ZrO₂ | – | – | – | 5~7 | 15~17 | – | |

| Cr2O₃ | – | – | – | – | – | – | |

| Outros | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 | ≤1.0 | |

| Size(mm) | Length:3600 &7200 &14400; Width:610 &1220; Thickness: 6-50;Other size are available as required. | ||||||

| Package | Woven bags or Cartons,and other package are available as required. | ||||||

| Recommended using temperature:In oxidizing or neutral atmosphere,100~250℃Recommended usingtemperature:In oxidizing or neutral atmosphere,100∽250℃lower than the maximum service temperature,In reductive atmosphere,200~350℃ lower than the maximum service temperature. | |||||||

The Standard size and package of SUNSHINE Ceramic Fiber Blanket

| Length (mm) | Width(mm) | Thickness (mm) |

| 7200/14400/28000 | 610(1220) | 6 |

| 7200/14400 | 610(1220) | 10/12.5 |

| 7200/10000 | 610(1220) | 15 |

| 7200 | 610(1220) | 20/25 |

| 6000/5000 | 610(1220) | 30 |

| 4500/3600 | 610(1220) | 40/50 |

| Package | Cartons or Woven bags | |

| Other sizes of products and packages are available as required. | ||